| TL;DR

The pharmaceutical packaging market is growing rapidly, making sustainability a global business priority. Regulations, patient awareness, and ESG commitments are driving a shift to eco-friendly packaging solutions. Key trends include recyclable and bio-based materials, lightweight designs, smart packaging, digital labelling, and mono-material blister packs. Fiber-based cartons, barrier coatings, and refillable systems are reducing single-use waste across the sector. Recyclable plastics (PET, HDPE, PP), bio-based polymers (PLA, PHA), and FSC-certified fiber packaging are leading materials. Transition strategies include sustainability audits, supplier partnerships, pilot programs, team training, and digital tracking tools. Compostable solutions like those from Greenworksbio provide a clean end-of-life alternative, breaking down fully into biomass, CO₂, and water. Sustainable packaging is no longer optional but the new operating standard for the pharmaceutical industry. |

Traditional pharmaceutical packaging often relies on single-use plastics and multi-layer materials that are difficult to recycle, contributing to long-term environmental waste. The pharmaceutical packaging market size is estimated to be worth USD 112.3 billion in 2025 and is anticipated to reach a value of USD 153.9 billion by 2035. (Source)

With stricter regulations, rising patient awareness, and global sustainability commitments, the shift toward sustainable pharmaceutical packaging is no longer optional; it’s a business imperative. Innovation in eco friendly pharmaceutical packaging material is enabling companies to maintain safety and compliance while reducing their carbon footprint.

From recyclable plastics to bio-based alternatives, brands are adopting solutions that enhance both environmental performance and consumer trust. This article explores the latest trends, key drivers, innovative materials, and transition strategies shaping the future of sustainable pharmaceutical packaging and how companies can lead in this evolving landscape.

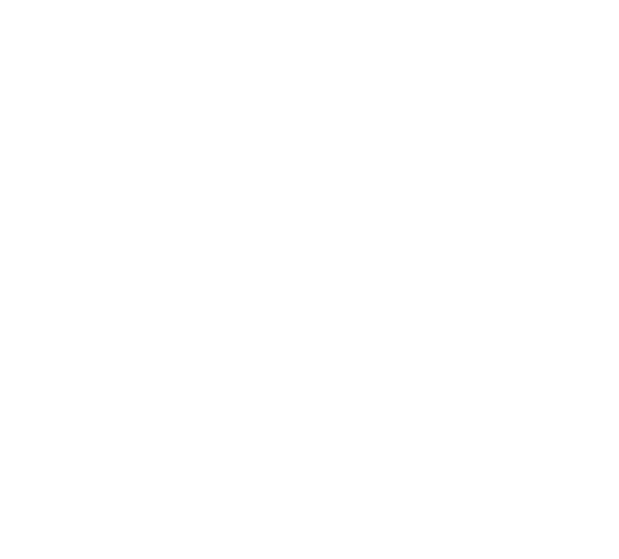

What Sustainability Trends Are Transforming Pharma Packaging in 2025?

The sustainable pharmaceutical packaging sector is undergoing rapid transformation, powered by stricter regulations, heightened patient awareness, and material innovations. In 2025, the industry is striking a balance between safety, compliance, and environmental responsibility, and the pace of change is accelerating.

1. Recyclable, Compostable, and Bio-Based Materials Take Centre Stage

More pharma companies are replacing fossil fuel–based plastics with recyclable PET, compostable films, and bio-based polymers like PLA and PHA. These materials cut dependency on petroleum while meeting stringent pharmaceutical barrier and safety standards.

The shift is measurable as the global sustainable pharmaceutical packaging market is expected to expand significantly, from approximately USD 87.24 billion in 2023 to USD 220.39 billion by 2030, reflecting a strong industry shift toward eco‑friendly materials like biodegradable and recyclable options. (Source)

2. Lightweight Packaging Slashes Emissions Without Compromising Safety

Lightweight designs, such as minimalist blister packs and reduced-wall bottles, are enabling pharmaceutical companies to use less raw material without compromising product safety or compliance. For example, Merck achieved a 25% reduction in packaging weight, directly lowering transportation needs and cutting greenhouse gas emissions across its supply chain (PharmaTech). Less weight means fewer emissions during shipping, making lightweight packaging a practical step toward greener operations.

3. Smart Packaging Strengthens Security and Traceability

Smart packaging technologies, including NFC chips, QR codes, serialization, and blockchain tracking, are transforming pharmaceutical supply chains. These tools not only improve patient confidence but also combat the global counterfeiting problem, which costs the industry billions annually. The anti-counterfeit pharmaceutical packaging market is forecast to grow from USD 102.45 billion in 2024. It is expected to grow at a CAGR of 8.65% from 2025 to 2030 (FMI, Grand View Research), largely due to the adoption of these advanced security features.

4. Digital Labelling Cuts Waste and Speeds Up Updates

Switching from printed leaflets to QR-linked digital labelling can significantly reduce environmental impact. In the U.S. alone, paper prescribing leaflets generate 500,000 tonnes of CO₂ emissions annually and consume nearly 11 billion gallons of water (Health Policy Partnership). Digital solutions allow instant updates to dosage, safety, and regulatory details without costly reprints, aligning with circular economy goals while improving accessibility for patients.

5. Mono-Material Blister Packs Revolutionize Recycling

Traditional multi-layer blister packs combine PVC, aluminum, and various polymers, making them difficult to recycle. Mono-material blister packs, made entirely from PET, PP, or HDPE, simplify the recycling process while maintaining product protection. Innovations in recyclable blister technology have shown a 47% reduction in carbon footprint compared to conventional formats (Plastics Industry Association).

6. Fiber-Based Secondary Packaging Gains Momentum

FSC-certified paperboard cartons and molded fibre trays are replacing petroleum-based plastics in secondary packaging. Lifecycle assessments show that switching from solid bleached sulfate (SBS) to lightweight folding boxboard (FBB) can cut carbon footprints by over 50% (Packaging Strategies). With growing consumer preference for paper-based materials, this shift is likely to dominate secondary packaging trends by 2030.

7. Advanced Barrier Coatings Protect Products and the Planet

Water-based and bio-based barrier coatings are emerging as sustainable alternatives to aluminum and multi-layer plastic films. These coatings maintain product shelf life while improving recyclability or compostability. Although specific percentages vary by manufacturer, early trials show significant gains in end-of-life recovery rates compared to conventional barrier systems, making them an important development for sustainable pharma packaging.

8. Modular and Refillable Packaging Reduces Single-Use Waste

Refillable pill dispensers and modular container systems are gaining traction in both OTC and wellness segments. The global refillable packaging market is valued at USD 45.6 billion in 2024 and is projected to grow to USD 62.6 billion by 2030 (Grand View Research). Early adopters report substantial reductions in single-use plastic waste over the product lifecycle, without sacrificing convenience or compliance.

Want recyclable, compostable, or bio-based options that pass pharma specs? Check out our certified compostable products.

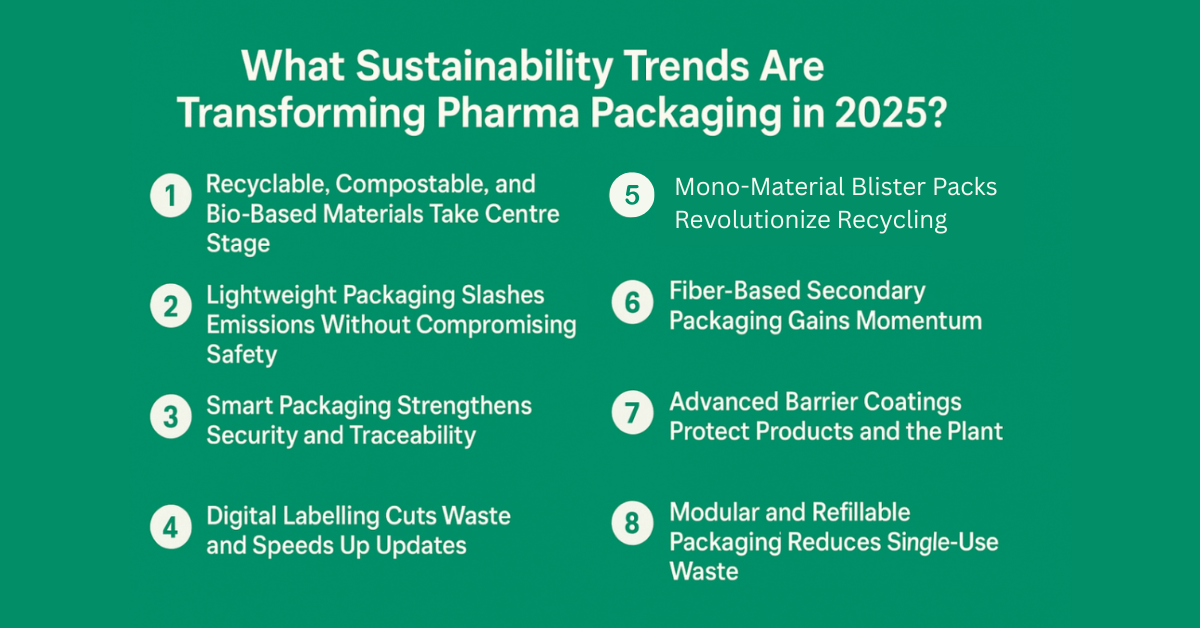

Which Materials Are Becoming the Best Choice for Sustainable Pharma Packaging?

The choice of eco friendly pharmaceutical packaging material plays a critical role in balancing product safety, regulatory compliance, and environmental performance. In the evolving sustainable pharmaceutical packaging landscape, certain materials are emerging as clear frontrunners, offering a mix of durability, recyclability, and reduced carbon impact. Below are the top options shaping the industry today.

1. Recyclable Plastics (PET, HDPE, PP)

Recyclable plastics such as PET, HDPE, and PP remain top choices for bottles, closures, and blister pack components. They meet pharmaceutical safety requirements, offer durability, and integrate easily into existing plastic recycling streams. With widespread recycling infrastructure, these materials help reduce landfill waste while maintaining product integrity.

2. Bio-Based Alternatives (PLA, PHA, Starch-Based Polymers)

Bio-based polymers like PLA, PHA, and starch-based plastics are gaining traction in blister films, sachets, and small containers. Derived from renewable resources, they offer a lower carbon footprint and, in some cases, compatibility with industrial composting facilities. These materials appeal to brands aiming to replace fossil fuel-based plastics with greener options.

3. Fiber-Based Packaging (FSC-Certified Paperboard and Inserts)

Fiber-based materials, including FSC-certified cartons, sleeves, and molded inserts, are rapidly replacing plastic trays and secondary packaging. Lightweight yet protective, they are easily recyclable in most paper waste streams and support sustainable packaging in the pharmaceutical industry by reducing environmental impact across the supply chain.

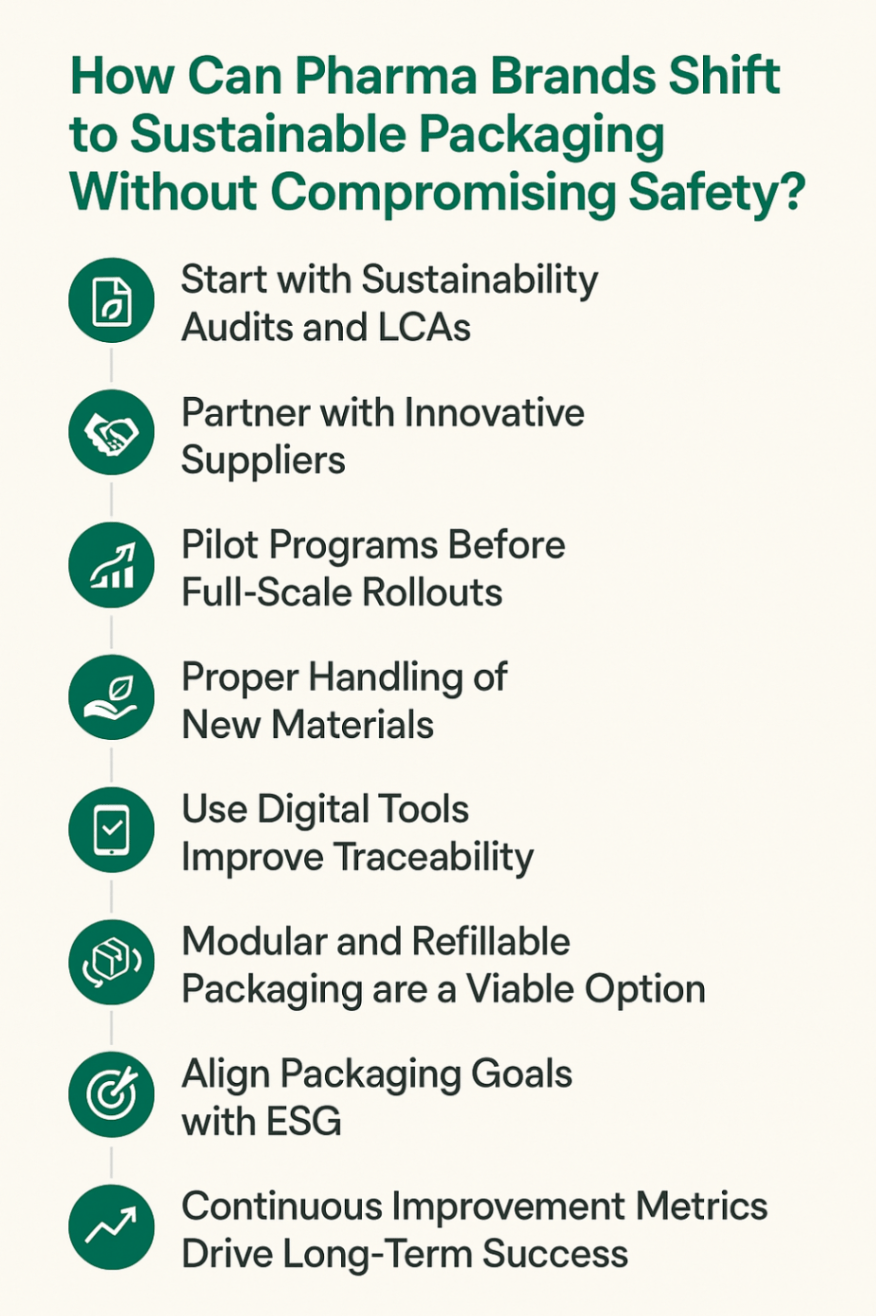

How Can Pharma Brands Shift to Sustainable Packaging Without Compromising Safety?

Switching to sustainable pharmaceutical packaging requires a careful balance between environmental goals and strict regulatory, safety, and quality requirements. Unlike other industries, the pharmaceutical sector faces higher stakes, where any change in packaging must still preserve the efficacy of the medicine, meet compliance standards, and protect patient safety.

To navigate this transition successfully, companies need a strategic, step-by-step approach that integrates sustainability into every stage of the packaging lifecycle.

1. Why Should Companies Start with Sustainability Audits and LCAs?

Begin with a comprehensive packaging audit, mapping materials, energy use, manufacturing impact, and end-of-life disposal. Use life cycle assessment (LCA) tools to evaluate sustainable packaging material against traditional options, focusing on carbon footprint, recyclability, and waste reduction potential. This ensures measurable data rather than assumptions back decisions.

2. How Can Partnerships with Innovative Suppliers Accelerate Change?

Collaborate with suppliers who can deliver pharma-grade sustainable solutions that meet regulatory standards such as ISO 15378 and provide compliance documentation (e.g., DMFs, extractables/leachables reports). Jointly develop materials, such as recyclable laminates, fiber-based cartons, or bio-based blister films, that align with both performance and environmental goals.

3. Why Are Pilot Programs Crucial Before Full-Scale Rollouts?

Before full-scale rollout, run controlled pilots to test packaging performance. Conduct stability studies, barrier property evaluations, sterilization compatibility checks, and distribution simulations (ISTA/ASTM standards). Document all findings for regulatory filings to ensure a smooth approval process.

4. How Can Training Ensure Proper Handling of New Materials?

New materials often require changes in storage, production line settings, and waste management processes. Train in-house teams, contract manufacturers, and logistics partners on updated SOPs, labeling requirements, and recycling or composting protocols.

5. How Do Digital Tools Improve Traceability and Compliance?

Adopt digital watermarking, QR codes, or blockchain-enabled tracking to improve supply chain visibility, enable better recycling sorting, and ensure compliance with anti-counterfeiting regulations. These tools can also provide patients with instant access to digital leaflets, reducing secondary packaging waste.

6. Could Modular and Refillable Packaging Become a Viable Option?

For certain over-the-counter (OTC) or wellness products, explore refillable container systems or modular packs that allow partial replacements rather than full disposals. This reduces raw material consumption and waste generation over the product’s lifecycle.

7. Why Align Packaging Goals with ESG and Regulatory Roadmaps?

Embed sustainability objectives into your company’s ESG strategy and annual reporting. Align packaging transitions with regional regulatory timelines to avoid rushed compliance changes that could disrupt supply chains.

8. How Do Continuous Improvement Metrics Drive Long-Term Success?

Track KPIs such as packaging weight reduction, recycling capture rates, CO₂ emissions saved, and patient feedback. Use this data to refine strategies, report progress to stakeholders, and maintain regulatory readiness.

From Intent to Impact: Compostable Done Right With Greenworksbio

Looking for genuinely greener packaging without sacrificing performance?

Greenworksbio helps brands make that leap, cleanly. We design and supply eco-friendly, certified-compostable alternatives that behave like conventional plastics in use, then break down at end-of-life into biomass, CO₂, and water—no greenwashed half-measures, just materials that deliver durability on the shelf and a responsible finish after use.

From retail to regulated categories, our catalog covers what most operations need to switch fast: compostable carry and courier bags, garbage and transparent bags, cutlery and tableware, bottles, plus extrusion, blow-molding, and injection-molding bio-resins. Need your current form factor, feel, or clarity? We’ll match specs with custom blends and film gauges so your teams don’t have to re-engineer the whole line.

Check out our products collection here.

Is Sustainable Pharmaceutical Packaging the Industry’s New Standard?

Sustainable pharmaceutical packaging is shifting from a nice-to-have to a core operational requirement. Tightening regulations, patient expectations, and ESG commitments are accelerating the adoption of recyclable, fiber-based, and bio-based solutions without sacrificing safety or shelf-life.

Technologies like mono-material blisters, recyclable laminates, and smart labels are closing the loop, while LCAs, pilots, and supplier partnerships de-risk implementation. Early movers will cut waste, reduce emissions, and strengthen brand trust, positioning themselves well as the sustainable pharmaceutical packaging market scales.

The path forward is clear: validate changes, train teams, track performance, and keep iterating. Sustainability isn’t a project; it’s the new operating system.

Frequently Asked Questions

What is the cost difference between sustainable and traditional pharmaceutical packaging?

Switching to sustainable packaging often results in higher upfront costs compared to conventional plastic packaging due to the use of innovative materials and advanced production processes. However, many pharmaceutical companies find these investments generate long-term savings through reduced waste and improved brand reputation, balancing cost impact over time.

How does sustainable packaging impact the shelf life and safety of medicine?

Sustainable packaging is engineered to maintain the shelf-life of medicines and patient safety by employing primary packaging materials that are compliant with strict pharmaceutical sector standards. Innovations like mono-material blister packs and improved barrier properties ensure drugs remain protected, meeting both regulatory and safety requirements.

What are the most promising innovations for improving pharmaceutical packaging recyclability?

Recent advancements, such as mono-material blister packs, fiber-based packaging, and recyclable laminates, are enhancing the recyclability of pharmaceutical packaging. These innovative packaging solutions simplify the recycling process for plastic and secondary packaging, making it easier to achieve circular economy goals and reduce plastic waste industry-wide.