| TL;DR

PLA is a plant-based bioplastic that is biodegradable under industrial composting, while PET is a petroleum-based plastic that is durable and recyclable. PLA is easy to print, eco-friendly in origin, and aesthetically appealing, but it is brittle, low in heat resistance, and degrades in sunlight and moisture. PET is tough, flexible, moisture- and UV-resistant, and recyclable, but it requires higher printing temperatures, is not biodegradable, and can scratch or warp without proper setup. PLA is best for compostable packaging, disposable products, and eco-conscious short-term use cases. Environmentally, PLA reduces reliance on fossil fuels and offers compostability, while PET reduces plastic waste through recycling and long-term usability. Greenworksbio offers certified compostable alternatives that go beyond PLA vs PET by eliminating microplastics and ensuring complete breakdown into biomass, CO₂, and water. |

When comparing PLA vs PET, the key question is: which material is truly more eco-friendly? PLA (Polylactic Acid) is a plant-based bioplastic known for its compostability, while PET (Polyethylene Terephthalate) is a petroleum-based plastic widely used in bottles and packaging.

Globally, over 500 billion PET bottles are used annually, but only less than 30% are recycled. PLA, on the other hand, is biodegradable, but only under industrial composting, not in landfills or oceans.

In the sections that follow, we’ll break down their pros and cons to help you make a more informed, eco-conscious decision.

What Exactly Is PLA and Why Is It Called a ‘Green’ Plastic?

PLA, or Polylactic Acid, is a biodegradable thermoplastic derived from renewable resources like corn starch, sugarcane, or cassava. As a bioplastic, it has gained popularity in both the packaging and 3D printing industries due to its eco-friendliness, ease of use, and relatively low production cost. Unlike petroleum-based plastics, PLA decomposes under industrial composting conditions, making it a greener alternative in the right environments.

What Makes PLA a Popular Eco-Friendly Plastic?

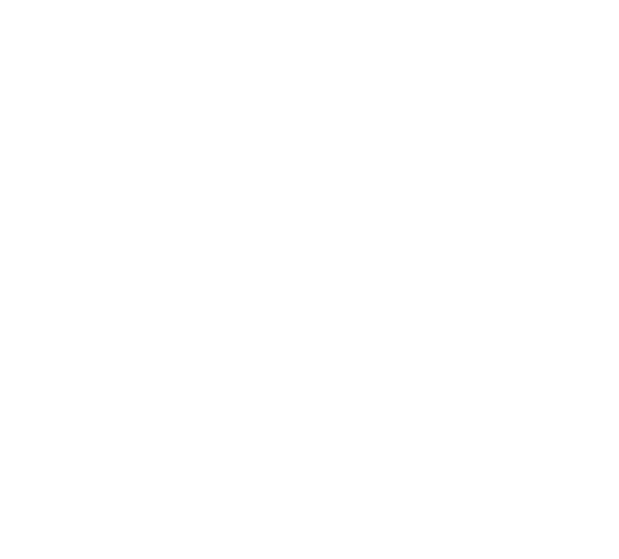

PLA (Polylactic Acid) offers a unique blend of sustainability and usability that makes it ideal for various applications. Here’s a breakdown of its standout characteristics:

- Biodegradability: PLA decomposes into natural compounds like water and carbon dioxide under industrial composting conditions (typically 50–60°C with high humidity). This makes it a more sustainable alternative to traditional plastics that persist for centuries.

- Low Melting Point: With a melting range of 180–220°C, PLA is easy to process in 3D printers and manufacturing without requiring extreme heat, reducing energy usage during production.

- Glossy, Aesthetic Finish: PLA has a naturally smooth and shiny surface, making it a top choice for consumer products, packaging, and display prototypes that need a polished appearance.

- Non-Toxic Emissions: When heated, PLA releases minimal to no harmful fumes, unlike petroleum-based plastics. This makes it safer for indoor 3D printing and suitable for limited-contact food applications.

- Pleasant or Neutral Odor: PLA typically gives off a mildly sweet, corn-like smell when melted, making it more tolerable in workspaces compared to the acrid smell of plastics like ABS.

What Are the Physical and Mechanical Properties of PLA?

PLA (Polylactic Acid) offers a good balance of strength and stiffness but has limitations in durability and weather resistance. Here’s a detailed look at its key physical and mechanical traits:

| Property | Description |

|---|---|

| Density | ~1.24 g/cm³ , Lightweight and easy to handle |

| Glass Transition Temperature | ~60–65°C, Begins to soften at relatively low heat |

| Melting Point | ~180–220°C , Suitable for low-energy processing |

| Tensile Strength | ~50 MPa, Offers good rigidity under tension |

| Elongation at Break | ~2–10%, Relatively brittle and prone to cracking under high stress |

| UV Resistance | Low, degrades over time with UV exposure |

| Moisture Absorption | Moderate, can deform or weaken in high-humidity environments |

Where Do We Actually Use PLA in Everyday Life?

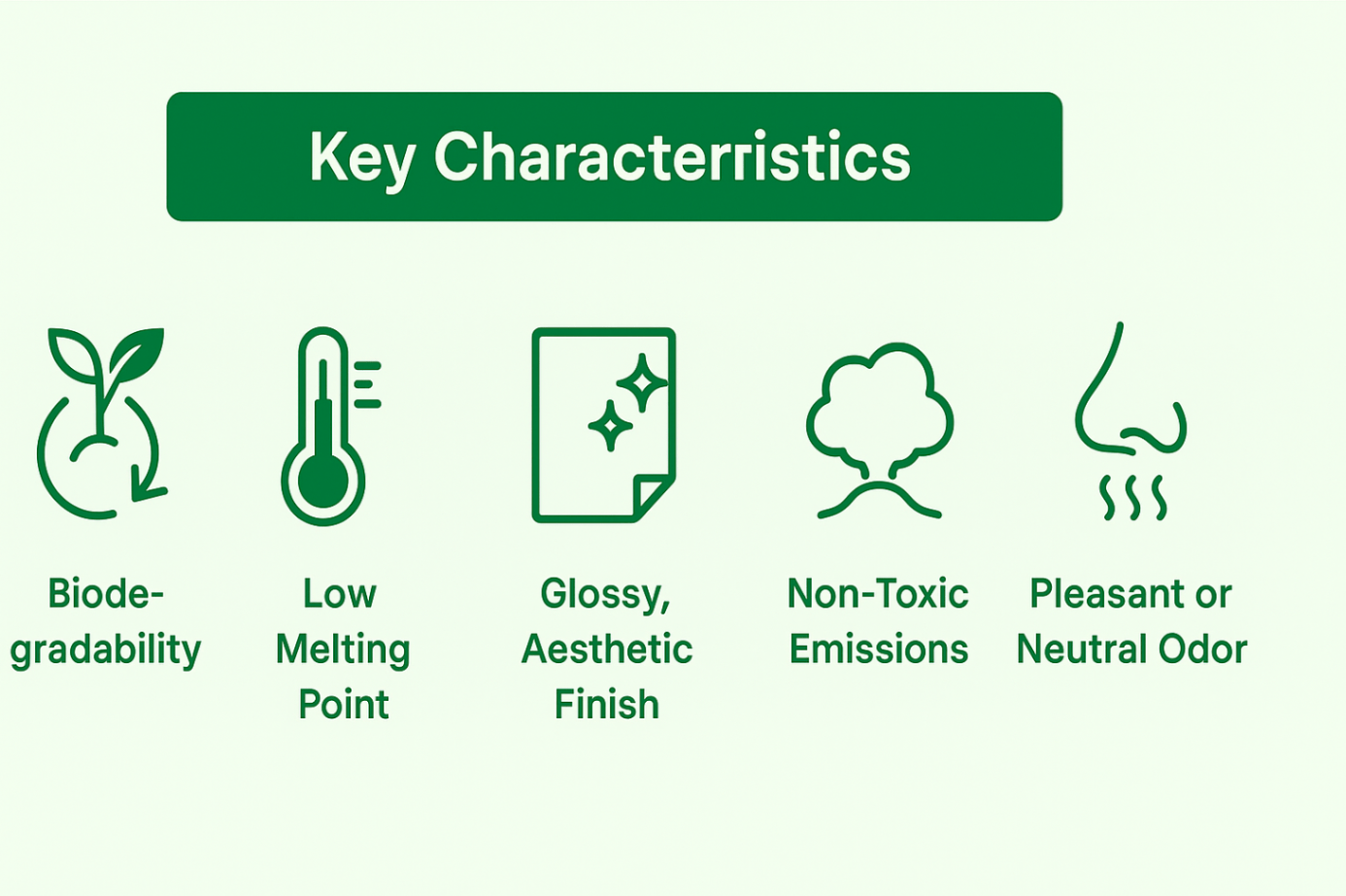

Thanks to its biodegradability, safety, and versatility, PLA is used across multiple industries. Below are its most common applications:

- Packaging: PLA is widely used in sustainable packaging solutions such as cups, clamshell containers, compostable trays, and films. Its biodegradable nature makes it ideal for single-use packaging where environmental impact is a concern, especially in the food and beverage industry.

- Medical Industry: In the medical field, PLA is used to create sutures, tissue scaffolds, and drug delivery systems. Its biocompatibility and absorbability make it suitable for temporary implants and internal applications that safely break down inside the body over time.

- Textiles: PLA is gaining popularity in eco-conscious fashion through its transformation into bioplastic fibers. These fibers can be woven into fabrics, offering a sustainable alternative to traditional petroleum-based textiles like polyester or nylon.

- 3D Printing: PLA is the go-to filament for FDM (Fused Deposition Modeling) 3D printers due to its low warping, ease of use, and non-toxic emissions. It’s especially favored by beginners and professionals who require fast prototyping with minimal setup complexity.

- Food Service & Disposable Products: From cutlery and straws to disposable plates and containers, PLA is extensively used in the food service sector. Eco-friendly restaurants and events often choose PLA products to align with zero-waste and compostable initiatives.

Is PLA the Perfect Plastic? Pros and Cons You Should Know

PLA offers several benefits that make it a popular choice for eco-friendly applications, but it also comes with limitations. Here’s a quick comparison:

| Advantages of PLA | Disadvantages of PLA |

|---|---|

| Eco-Friendly Origin: Made from renewable resources like corn starch | Limited Heat Resistance: Softens at ~60°C, unsuitable for high-temperature use |

| Biodegradable: Breaks down in industrial composting environments | Brittle: Less impact-resistant, prone to cracking under stress |

| Low Printing Temperature: Requires less energy to print (~180–220°C) | Low UV and Moisture Resistance: Degrades in sunlight and humid conditions |

| Minimal Warping: Prints well without a heated bed | Composting Limitations: Needs industrial composting, won’t degrade in a landfill |

| Food Safe: Generally non-toxic, suitable for limited food contact | Not Ideal for Functional Parts: Not durable enough for load-bearing use |

| Glossy Finish: Aesthetic appeal for prototypes and consumer packaging |

What Makes PET So Popular in Packaging and Printing?

PET stands for Polyethylene Terephthalate. It is a durable, semi-rigid thermoplastic with added flexibility and clarity from glycol modification. PET is widely used in packaging, 3D printing, medical devices, and retail displays due to its excellent balance of toughness, chemical resistance, and ease of processing.

Unlike PLA, PET is not biodegradable, but it is recyclable, making it a popular choice for long-lasting, reusable products and structural components.

Why Is PET a Go-To for Tough, Transparent Plastics?

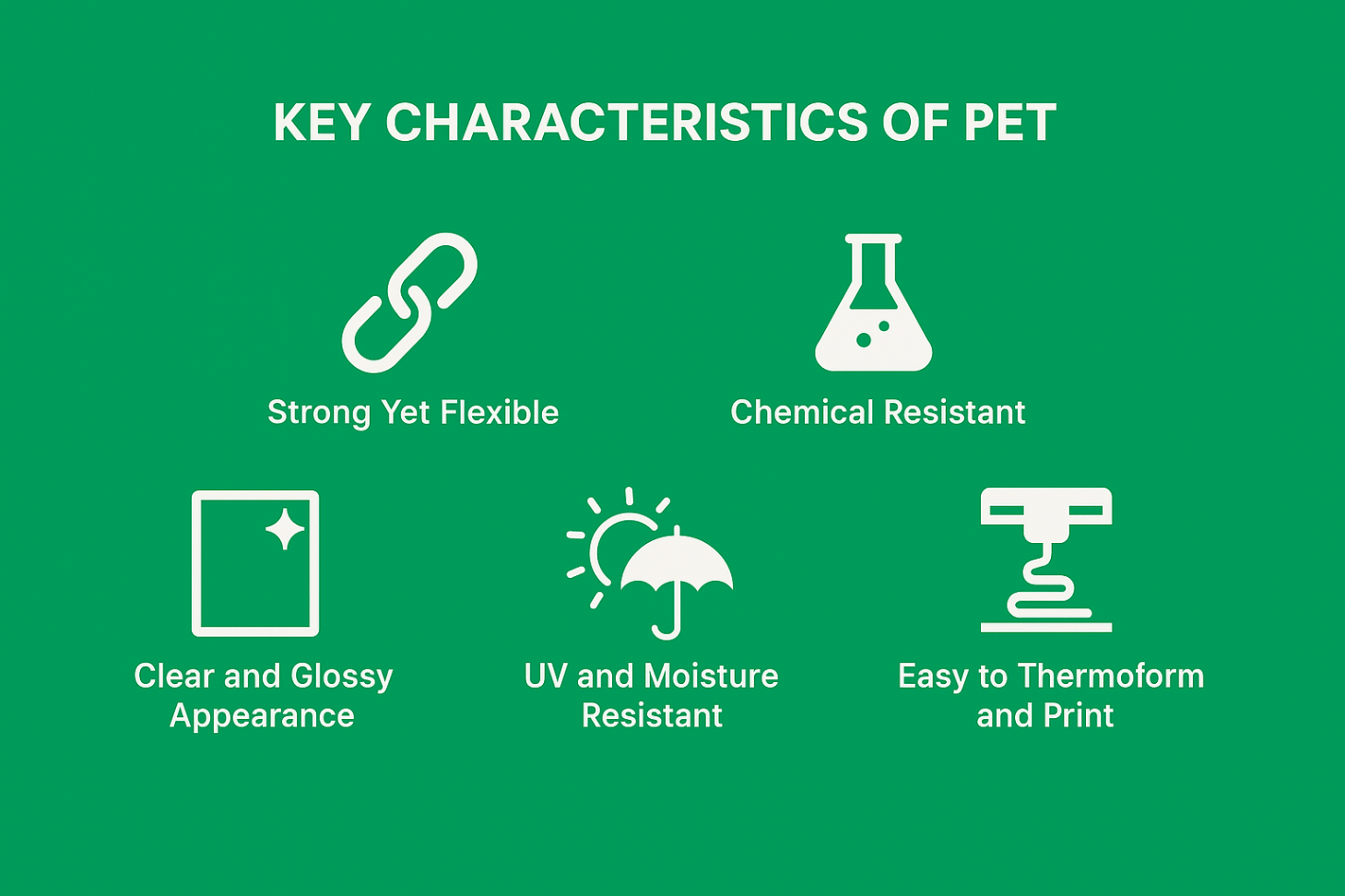

PET (Polyethylene Terephthalate) stands out for its strength, clarity, and ease of use, making it a popular material across packaging, fabrication, and 3D printing.

- Strong Yet Flexible: PET offers an ideal balance of rigidity and flexibility. Unlike PLA, it is less brittle and more impact-resistant, which makes it suitable for functional and load-bearing parts.

- Chemical Resistant: PET resists a wide range of substances, including alcohols, oils, and mild solvents. This makes it suitable for applications in medical, industrial, and food-safe environments.

- Clear and Glossy Appearance: Its high optical clarity and smooth surface give PET a glass-like, glossy finish, perfect for transparent packaging, displays, and aesthetic parts that require visibility.

- UV and Moisture Resistant: PET performs well under exposure to sunlight and humidity. This makes it a reliable material for outdoor applications and high-humidity settings like kitchens or labs.

- Easy to Thermoform and Print: PET is easy to work with in both fabrication and 3D printing. It has excellent layer adhesion, minimal warping, and does not typically require an enclosure for printing, making it user-friendly even for beginners.

What Are the Physical and Mechanical Properties of PET?

PET combines strength, flexibility, and durability, making it suitable for a wide range of functional applications. Below is a breakdown of its key physical and mechanical properties:

| Property | Value / Description |

|---|---|

| Density | ~1.27–1.38 g/cm³ , Slightly heavier than PLA |

| Glass Transition Temp | ~80°C, Provides better thermal resistance than PLA |

| Melting Point | ~230–260°C , Requires higher nozzle temperatures for 3D printing |

| Tensile Strength | ~50–60 MPa, High strength under tension, suitable for structural parts |

| Elongation at Break | ~20–30%, Greater flexibility and ductility compared to PLA |

| UV Resistance | Moderate to High, Withstands light exposure better than PLA |

| Moisture Resistance | High, Excellent performance in humid or wet environments |

How Is PET Shaping Modern Packaging and Manufacturing?

Thanks to its durability, clarity, and chemical resistance, PET has become a go-to material across a variety of industries. Whether in retail packaging or technical manufacturing, its versatility makes it suitable for both aesthetic and functional applications.

- Packaging and Displays: PET is widely used in retail packaging, signage, and product display units. Its high transparency, impact resistance, and formability make it ideal for applications like blister packs, clamshell containers, and shelf-ready displays that require both clarity and durability.

- Medical Applications: Thanks to its chemical resistance and sterilizability, PET is commonly used in the medical field. It serves in sterile packaging, protective face shields, and labware, where hygiene and safety are paramount. Its ability to be molded into complex shapes without compromising clarity is a significant advantage.

- 3D Printing: In 3D printing, PET bridges the gap between PLA and ABS. It is valued for producing mechanical parts, functional prototypes, tool handles, and enclosures that require strength, flexibility, and temperature resistance. PET’s excellent layer adhesion and minimal warping make it a preferred material for reliable prints.

- Industrial Applications: PET is also used in manufacturing environments for machine guards, protective covers, and fabricated components. Its impact strength, wear resistance, and ability to withstand harsh chemicals make it a dependable choice for both protective and operational components.

Is PET the Workhorse of Modern Plastics? Pros and Cons Revealed

PET offers a solid balance of strength, clarity, and printability, making it a favorite for both professional and personal use. However, like any material, it comes with trade-offs. Here’s a quick comparison to help you evaluate whether PET fits your needs:

| Advantages of PET | Disadvantages of PET |

|---|---|

| Durable and Impact-Resistant: Tougher than PLA and suitable for functional parts | Higher Printing Temperature: Requires 230–260°C, which some printers can’t handle |

| Chemical Resistance: Withstands oils, alcohols, and cleaning agents | Stringing and Oozing: Needs dialed-in retraction settings to avoid print defects |

| Flexible Yet Rigid: Resists snapping while offering solid structural integrity | Not Biodegradable: Unlike PLA, it doesn’t break down in composting environments |

| Transparent and Glossy Finish: Great for clear or aesthetic parts | Can Scratch Easily: The Surface is more prone to cosmetic wear |

| Moisture and UV Resistance: Performs well outdoors and in humid spaces | Poor Bed Adhesion Without Prep: Needs solid first-layer adhesion to prevent warping |

| Recyclable: Accepted in many recycling streams, reducing plastic waste |

PLA vs PET: Which Material Performs Better?

Choosing between PLA vs PET depends on your specific use case, whether it’s ease of printing, strength, environmental performance, or outdoor durability. Below is a detailed side-by-side comparison to help you understand how these two popular materials differ across key performance areas.

| Feature | PLA (Polylactic Acid) | PET (Polyethylene Terephthalate Glycol) |

|---|---|---|

| How Easy Is It to Print? | Very easy to print; ideal for beginners. Prints at lower temperatures with minimal warping | Easy to print but needs tuning (higher temp, retraction, slower speed) |

| Which One Is Stronger? | Moderate tensile strength but brittle; prone to cracking under load | Tougher and more durable; better suited for mechanical and load-bearing parts |

| How Well Do They Resist the Elements? | Poor resistance to UV and moisture; not recommended for outdoor use | Excellent resistance to water and UV; performs well outdoors |

| Which Offers More Flexibility? | Stiff and brittle; low elongation at break (2–10%) | More flexible and ductile; elongation at break ~20–30% |

| How Do They Handle Heat? | Low heat tolerance; softens around 60–65°C | Higher thermal resistance; maintains integrity up to 80°C+ |

| Are They Biodegradable or Recyclable? | Biodegradable under industrial composting; not recyclable in most systems | Not biodegradable but fully recyclable in many facilities |

| What About Other Environmental Factors? | Made from renewable plant-based sources; low carbon footprint | Made from petrochemicals but long-lasting and reusable; less waste over time |

At Greenworksbio, we combine the durability of PET with the sustainability of PLA, without the compromise. Explore our certified compostable products that deliver performance and a clean, microplastic-free end of life.

PLA vs PET: Why Greenworksbio Offers a Better Alternative

When comparing PLA vs PET, the choice often comes down to balancing sustainability with performance. While both materials have eco-forward benefits, PLA being biodegradable and PET being recyclable, they also come with trade-offs like limited heat resistance or lack of compostability in real-world conditions.

At Greenworksbio, we go beyond the PLA vs PET debate by offering certified compostable solutions that outperform both in end-of-life impact. Our plant-based materials don’t just reduce plastic waste; they eliminate it. From compostable carry bags and cutlery sets to injection-grade bio-resins and industrial packaging, every product we design is engineered to fully break down into biomass, CO₂, and water, leaving no microplastics behind.

Conclusion

When choosing between PLA vs PET, it’s essential to consider your specific application and environmental goals. PLA is ideal for eco-friendly, compostable packaging and non-functional prototypes, thanks to its plant-based origin and ease of use. PET, on the other hand, is more suitable for functional parts, outdoor use, and products requiring greater durability, flexibility, and chemical resistance. While PLA wins on biodegradability, PET stands out for its recyclability and toughness. Ultimately, both materials offer sustainable advantages. Understanding the trade-offs of PLA vs PET helps you make smarter, greener material choices for your project or business.

Frequently Asked Questions

Is PLA better than PET?

PLA is often the best choice for eco-friendliness due to its plant-based origin and lower carbon footprint during PLA production. It prints at lower temperatures and decomposes in industrial composting facilities, while PET offers superior durability and water resistance for structural parts.

Is PLA plastic safe for pets?

PLA is made from lactic acid and is safe in non-edible applications like 3D-printed pet accessories. However, it’s not suitable for chew toys due to brittleness, especially when exposed to higher temperatures, which could create sharp edges.

Is PLA or PET safer for food packaging in India?

PET is usually the right material for Indian food packaging because of its water resistance, chemical stability, and ability to withstand high heat. PLA, while made from renewable resources, has a lower melting point and requires specific conditions for safe use.

Can PLA be recycled alongside regular PET plastic?

No, PLA and PET are different materials and can’t be mixed in plastic recycling streams. Their key differences in structure and additives contaminate plastic bottles processed through conventional systems.

Which material is usually preferred for eco-friendly applications: PLA or PET?

PLA is preferred for eco-friendly uses thanks to its lower greenhouse gas emissions, renewable origin, and compatibility with industrial composting facilities. PET or PETG may be better suited for mechanical components, better UV resistance, and higher temperatures.

How does plastic compare with alternative materials in the packaging sector?

Traditional plastic offers strength but performs poorly in life cycle assessment compared to additive manufacturing materials like PLA, paper, and glass. Compostable bioplastics like PLA reduce plastic waste, cut emissions, and align with specific requirements for low-impact printing materials.