| TL;DR

PLA and PBAT are biodegradable materials changing the plastics game. PLA offers a clear finish and structure, PBAT adds flexibility and strength. Industrial composting allows blends to decompose in 150–180 days. Greenworksbio helps brands adopt these materials in real-world B2B packaging. |

The global plastic crisis is no longer a future threat; it’s a present-day emergency. From mounting plastic waste in landfills to rising pressure from governments and consumers, industries worldwide are being forced to rethink their packaging choices. The demand for sustainable alternatives to plastic has never been greater.

PLA and PBAT have emerged as two of the most talked-about biodegradable materials driving the future of sustainable packaging. But are they just buzzwords, or do they offer a real solution to the plastic problem?

In this blog, we break down what makes PLA and PBAT viable contenders in the shift away from conventional plastics, how they’re being used, what challenges manufacturers face, and how Greenworksbio is leading the charge toward scalable, certified compostable solutions in India.

How Is the Global Plastics Landscape Changing?

The global packaging industry is facing a turning point. In recent years, plastic pollution has pushed regulators and brands to reconsider the environmental impact of traditional plastics. As a result:

- Single-use plastic bans are spreading across India, the EU, and Southeast Asia.

- Compostable plastics regulations (e.g. CPCB and EN 13432) are becoming more stringent.

- Consumer pressure for sustainable plastic materials is intensifying.

- Brands are under pressure to move away from conventional plastics used in plastic cups, plastic bags, and plastic packaging.

This shift is fueling increasing demand for materials like PLA and PBAT, which offer a lower carbon footprint and align with circular economy goals.

What Are PLA and PBAT, and Why Combine Them?

As businesses seek sustainable plastic materials, PLA and PBAT have emerged as leading biodegradable polymers. When combined, they offer a strong alternative to traditional plastics, balancing performance with environmental responsibility. Let’s discuss this in detail.

What Is PLA?

Polylactic Acid (PLA) is a bio-based polymer made from renewable resources such as corn starch and sugarcane. It’s derived from lactic acid, a fermentation by-product, making it both plant-based and compostable under the right conditions.

Key applications of PLA include:

- Clear packaging films

- Disposable tableware like plastic plates

- Agriculture films and 3D printing filaments

- Used as liners in coffee capsules

However, while it’s compostable, it’s also brittle and lacks flexibility. That’s where PBAT steps in.

What Is PBAT?

Polybutylene Adipate Terephthalate (PBAT) is a biodegradable copolymer made from adipic acid, terephthalic acid, and 1,4-butanediol. Though derived from petroleum, it’s designed to break down efficiently in industrial composting systems and, under the right temperature and microbial conditions, can also biodegrade in soil or home compost environments, though more slowly.

PBAT is valued for:

- Heat resistance

- Toughness and flexibility

- Compatibility with blown film and molded products

Why Combine PLA + PBAT?

PLA provides a transparent, rigid finish, while PBAT adds elasticity and durability. Together, they create a viable alternative to plastic bottles, food storage containers, and coffee cups used across various industries.

At Greenworksbio, we leverage this combination in bottles, cutlery, and tableware to balance performance and sustainability.

Want to know how these solutions can fit your business? Explore our product range to discover certified, customizable compostable packaging options.

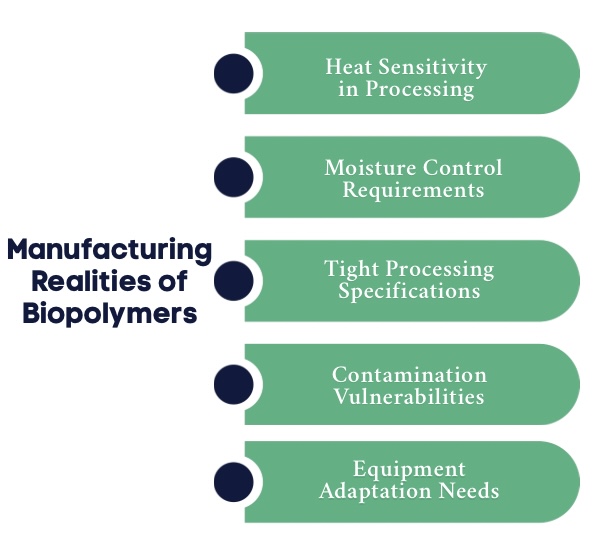

What Are the Manufacturing Realities of Biopolymers?

While PLA and PBAT are gaining popularity as sustainable packaging materials, they also introduce new manufacturing complexities. From temperature sensitivity to contamination risks, producers must rethink traditional plastic processing methods to handle these biodegradable polymers effectively.

1. Why Does Temperature Sensitivity Matter in Biopolymer Processing?

Both PLA and PBAT are sensitive to heat. High processing temperatures can cause discoloration, brittleness, and even destroy the material’s compostability, especially during extrusion or molding of thin products.

2. How Important Is Moisture Control for PLA and PBAT?

Controlling moisture is critical. If PLA or PBAT are not thoroughly dried before processing, they can degrade through hydrolysis, weakening the final product and leading to inconsistencies during production.

3. What Processing Conditions Are Required for Biopolymers?

Manufacturing with PLA and PBAT demands strict precision. Specific drying times, extrusion temperatures, and material feed consistency are necessary to avoid line blockages and downtime. These are common issues when using conventional equipment without modification.

4. Are there Contamination Risks During Production?

Biopolymers are more vulnerable to contamination than traditional plastics. Dust, residual moisture, or incompatible materials can compromise compostability and reduce product quality. Clean-room protocols and material handling discipline are essential.

5. Do Biopolymers Require Specialized Equipment?

Yes. Traditional processing lines often fall short. PLA and PBAT may require special screw designs, degassing systems, and better temperature and humidity control to maintain stability during production, particularly in blown film or extrusion applications.

Which Applications Are Powering the Shift to PLA and PBAT?

As global industries rethink packaging strategies, the real-world applications of PLA and PBAT are expanding rapidly. These biodegradable polymers are no longer limited to niche products; they’re being integrated into mainstream packaging formats across sectors like food, retail, agriculture, and logistics. The versatility of each material plays a major role in driving adoption of these eco-friendly packaging solutions.

What Are PLA-Based Products Used For?

PLA is ideal for applications where clear, see-through finish, structure, and compostability are key. Its plant-based origin makes it suitable for a range of disposable and semi-rigid formats.

- Clear packaging films used in food and retail.

- Disposable cutlery and compostable trays.

- Packaging for lunch boxes and clear food containers, designed for on-the-go sustainability.

Where Does PBAT Fit Best?

PBAT is preferred for flexible packaging and products that need elasticity and heat resistance. It mimics the properties of traditional plastic bags but offers the benefit of biodegradability under industrial composting conditions. Common uses of PBAT include:

- Flexible bags and cling films for perishables.

- Garbage bags, agriculture sheets, and liners.

- Durable packaging used in conditions requiring thermal stability and strength.

How Is Greenworksbio Enabling Real-World Adoption?

At Greenworksbio, we support the transition to compostable packaging through both product innovation and compliance alignment.

- We provide custom bottles, cutlery, and tableware tailored for food, retail, and hospitality sectors.

- Our compostable resins are used in carry bags, courier bags, and molded products.

- All materials are developed to meet specific conditions required by CPCB and ISO 17088 certifications.

Our solutions offer a greatalternative to conventional plastic packaging, empowering businesses to reduce their environmental impact while meeting functional and regulatory demands.

What Are the Compostability and End-of-Life Considerations of PLA and PBAT?

One of the most important benefits of PLA and PBAT lies in what happens after their use. Unlike traditional plastics, which can persist in the environment for hundreds of years, these materials are designed with a defined, controlled end-of-life pathway.

Under industrial composting conditions, typically involving high temperatures and controlled humidity, PLA+PBAT blends can fully decompose within 150 to 180 days. Some specially formulated blends also support home composting, breaking down at lower temperatures without leaving behind microplastics or toxic residues.

But compostability isn’t just about material science, it’s about infrastructure and education. That’s why Greenworksbio works closely with businesses to ensure proper disposal practices and alignment with key standards, including:

- CPCB rules under India’s Plastic Waste Management framework.

- EN 13432 (TÜV), the European standard for industrial compostability.

- ISO 17088, which sets global benchmarks for compostable plastics.

This focus on certification and guidance ensures that sustainability isn’t just a marketing claim; it’s built into the product’s full lifecycle, from design to degradation.

Looking for packaging ideas that stand out and support the planet? Explore our top creative and eco-friendly solutions.

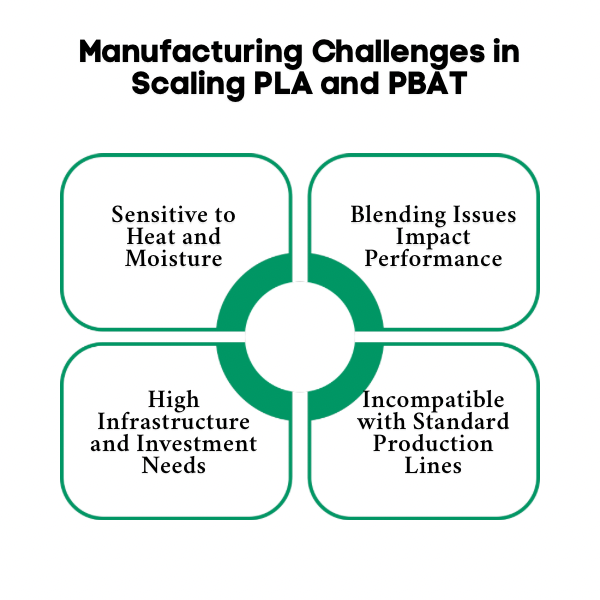

What Are the Manufacturing Challenges in Scaling PLA and PBAT?

As promising as PLA and PBAT are, scaling their use beyond pilot programs or niche applications presents real operational hurdles. From material handling to infrastructure limitations, businesses must address multiple bottlenecks before these bioplastics can truly replace conventional plastics at scale. Here’s a breakdown of what’s standing in the way, and how Greenworksbio is helping solve it.

1. Why Is Processing Sensitivity a Concern?

PLA and PBAT are highly sensitive to temperature and moisture during manufacturing. If not handled under the right conditions, they can become brittle or lose their compostability. Overheating during extrusion or improper drying may compromise product quality and performance, especially in thin films or flexible formats.

2. What Makes Blending and Compatibility So Critical?

Blending PLA and PBAT isn’t just about mixing raw materials; it requires precise dispersion to ensure consistent performance. Poor compatibility between the two can weaken the final product, leading to flexible packaging that tears easily, faulty seals, and unplanned downtime on production lines.

3. What Infrastructure and Investment Barriers Exist?

Establishing biopolymer production requires significant capital investment, especially for extrusion and compounding lines optimized for bioplastics. Compounding this challenge is the limited availability of industrial composting infrastructure in many Indian cities. Brands pushing for change can’t rely solely on own reusable cup campaigns; they need systemic, end-to-end support.

4. What Are the Common Production Line Challenges?

Traditional equipment isn’t always well-suited for processing PLA and PBAT. Manufacturers often face issues like line blockages, slower throughput, and inconsistent output. These materials may require specialized screw designs, precise degassing, and strict control of feedstock moisture to maintain efficiency and reduce waste.

How Does Greenworksbio Support Scalable Production?

At Greenworksbio, we address these barriers with tailored PLA+PBAT blends engineered for Indian conditions. We provide hands-on technical support to help manufacturers reduce food waste, improve line performance, and meet growing demand for sustainable packaging alternatives to plastic and paper. This approach ensures that adopting bioplastics is not just environmentally responsible, but operationally viable too.

What Are the Global Market Trends for PLA and PBAT?

The market for biodegradable plastics like PLA and PBAT is experiencing rapid growth, driven by regulatory action, sustainability commitments, and consumer pressure.

Several key factors are accelerating the global adoption of PLA and PBAT:

- Sweeping bans on plastic waste across various countries and mandates for compostable plastics in packaging and food service.

- Key sectors, like FMCG, agriculture, e-commerce, and pet food, are increasingly turning to biopolymers for specific applications like food wraps, mailers, and produce packaging.

- Major global brands are phasing out traditional plastics in favor of sustainable alternatives to plastic, especially in large scale operations where compliance and public image matter.

According to European Bioplastics (EUBP), global bioplastics production capacity is projected to increase from approximately 2.18 million tonnes in 2023 to about 7.43 million tonnes by 2028, with PLA and PBAT leading the expansion due to their range of applications, compostability, and compatibility with existing processing systems.

Will Bioplastics Like PLA+PBAT Become the Standard?

Will PLA and PBAT remain stepping stones, or become the new global standard for sustainable packaging?

Regardless of the answer today, these materials are already paving the way for sustainable alternatives to single-use plastics, offering a balance of performance, compostability, and regulatory compliance.

As public awareness rises and environmental policies tighten, biodegradable materials like PLA and PBAT present a viable path forward.

But they aren’t silver bullets. Infrastructure, education, and manufacturing support, like what Greenworksbio offers, are critical to making their adoption truly impactful and scalable.

What Does the Future Hold for PLA and PBAT?

The rise of PLA and PBAT is more than just a trend; it’s a clear signal of where the future of packaging is headed. Across sectors, global brands are actively moving away from plastic bottles, plastic cups, and the broader plastic habit, opting instead for glass containers, biodegradable plastics, and encouraging consumers to bring their own containers.

At the same time, innovation continues to push boundaries. We’re seeing rapid progress in marine-safe bioplastics, faster-degrading blends, and more scalable processing technologies, all aimed at improving performance while reducing environmental impact.

Businesses that delay this shift risk:

- Falling short on compliance requirements.

- Losing ground to more sustainable competitors.

- Facing reputational damage in an eco-conscious market.

The question isn’t if the industry will change; it’s how ready you are to lead that change.

Frequently Asked Questions

What other biodegradable plastics are commonly used as alternatives to PLA and PBAT?

Alternatives to biodegradable PLA PBAT include PHA, PBS, and starch-based bioplastics. These materials vary in strength, degradation time, and use cases, and are increasingly adopted in food packaging, agriculture, and medical applications where compostability and safety are essential.

Are PLA and PBAT safe for food contact, and what certifications or standards do they need to meet?

Yes, PLA and PBAT are food-safe when produced correctly. They must meet certifications like ISO 17088, EN 13432, CPCB norms, and sometimes FDA or EFSA standards, depending on the region and intended food-contact application.

How do the costs and manufacturing processes of PLA and PBAT compare to traditional plastics like PET or PE?

PLA and PBAT generally have higher production costs than PET or PE due to raw material sourcing and specialized processing needs. They also require stricter temperature and moisture control, making manufacturing more sensitive and less scalable without tailored equipment.