We often hear about the carbon footprint of plastic—but that’s only part of the story. What’s less talked about is the growing body of research linking plastic to microplastics in human organs, hormonal disruption, and even threats to food systems via pollinator decline.

Plastic waste isn’t just bad for the planet—it’s showing up in our bodies, in our water, and across our food chain. And while switching to sustainable materials feels like the obvious move, it’s not always clear which alternatives actually work—and which are just dressed-up versions of the same problem.

This blog will break down which plastic alternatives are genuinely functional, safe, and scalable—so you can make decisions that are better for your operations, your health, and the environment.

Why Replacing Plastic Isn’t Optional Anymore?

Most people working in product, ops, or supply chain already understand the scope of the plastic problem. But the scale keeps shifting—and fast.

Plastic isn’t just ending up in oceans and landfills anymore.

It’s in our water, our soil, even our food systems. Microplastics have been found in human blood, fetal tissue, and the deepest parts of the ocean. And despite decades of recycling initiatives, over 90% of plastic still never gets recycled (Source).

What’s changed is that sustainable sourcing is no longer just a nice-to-have. It’s being baked into procurement policies, investor expectations, and compliance checklists across industries.

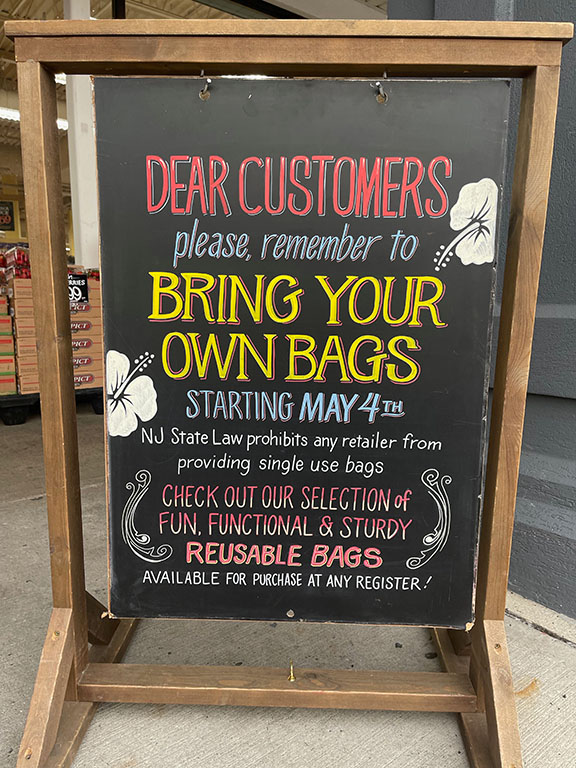

- Retailers are pushing suppliers to meet compostable or recyclable standards.

- Exporters are adapting to international bans on certain plastic types.

- Consumers—especially younger ones—are actively choosing lower-impact brands.

As a result, starch-based polymers—particularly blends of PLA and PBAT—are gaining rapid traction. These materials offer the industrial compostability, strength, and versatility needed for everything from mailers to carry bags. And unlike many imported or filler-heavy alternatives, starch-based films produced in India can be tuned for durability, sealability, and waste stream compatibility—making them a viable fit for both compliance and scale.

Sustainability today isn’t just about reducing plastic—it’s about building systems that are ready for regulation, reputation, and long-term resilience.

What are the 5 Smarter Products Powering the Plastic-Free Shift?

While debates over policy and regulation continue, many teams aren’t waiting around. They’re already adopting smarter alternatives—not as PR moves, but because these products are genuinely working across supply chains, events, and households.

For example, popular snack brand PepsiCo promised to have designed 98% of their packaging to be recyclable, compostable, biodegradable or reusable (RCBR) and that 92% of their packaging will be overall RCBR — that is, both designed to be RCBR and RCBR based on availability of end-of-life solutions by the end of 2025 (Source).

Inspired enough to learn more about the shift? Here are some of the plastic-free products that are gaining traction across industries:

1. Compostable Garbage Bags Are Becoming the Default in Eco-Conscious Buildings

Green housing developers, LEED-certified buildings, and smart campuses are replacing black bin liners with compostable alternatives, especially in regions where source segregation is enforced.

Municipal mandates like those in Maharashtra (India) have banned non-compostable garbage bags since 2018, driving higher institutional demand (Source).

Why it’s working:

- No changes to disposal behavior

- Works well in wet and dry waste segregation systems

- Complies with municipal composting mandates in many cities

Explore compostable garbage rolls here.

2. Compostable Courier Bags Are Becoming the Go-To for D2C Brands

Fashion and beauty brands, especially those with younger or international customers, are phasing out plastic poly mailers in favor of compostable alternatives that still look premium.

Why it’s working:

- Compatible with thermal labels and automation

- Keeps brand image consistent with sustainability values

- Accepted by most fulfillment partners and platforms

- Matches what 44% of D2C brands are prioritizing this year: compostable packaging (Source)

Explore compostable courier bags here.

3. Cutlery and Tableware for Events Are Quietly Going Plastic-Free

From corporate offsites to community events, compostable tableware is now widely available, stylish, and high-performing—even in bulk. What started as a niche offering is now a necessity—and the event industry has adapted fast.

Why it’s working:

- No need for cleanup logistics

- Avoids regulatory headaches now that India’s 2022 SUP ban covers single-use cutlery

- Matches the sustainability criteria now baked into many corporate RFPs

Explore compostable cutlery and tableware here.

4. Transparent Compostable Bags Are Solving a Retail Visibility Problem

Retailers, especially in pharma and wellness, need packaging that shows the product but avoids plastic. Transparent compostable bags now offer that balance—and brands are taking notice.

Why it’s working:

- Keeps the visual appeal of clear film

- Seamless switch for sealing, labeling, and shelf display

- Already rolled out by over 40 Indian brands across health and grocery categories (Source)

When form and compliance align, adoption happens fast.

Explore transparent compostable carry bags here.

5. Plant-Based Packaging Is Going from Niche to Normal in FMCG

Compostable packaging isn’t just a startup play anymore. Larger FMCG players are starting to explore it for select SKUs, particularly in snacks, dry foods, and quick-serve packaging.

Why it’s working:

- Performs comparably to conventional film

- Biodegrades in commercial compost setups

- Eases regulatory and PR pressure in global markets

Explore plant-based packaging solutions →

How to Choose the Right Plastic Alternative for Your Needs?

Not every “eco-friendly” material is the right fit for every use case. Whether you’re sourcing packaging, tableware, or logistics materials, it’s not just about being compostable—it’s about being compatible with your systems, your stakeholders, and your sustainability goals.

Here’s what to look for when evaluating plastic alternatives:

1. Check for Certifications That Actually Mean Something

Terms like “biodegradable” or “eco-safe” can be misleading unless backed by certifications. The gold standards for compostable products are:

- CPCB (Central Pollution Control Board): Mandates compliance with compostability standards for products sold in India under plastic waste rules.

- CPET (Central Institute of Petrochemicals Engineering & Technology): Provides laboratory testing and technical validation for compostable materials.

- TÜV Austria (Global/Accepted in India): Offers “OK Compost Industrial” and “OK Compost Home” marks, recognized in global and Indian regulatory environments.

Tip: If a product claims to be compostable but doesn’t list a certification body or test standard, it’s worth digging deeper.

2. Start the Right Conversations with Your Suppliers

Once you’ve evaluated your packaging needs, bring your supplier into the conversation. A good partner will translate sustainability goals into real-world product options—without compromising performance.

Ask smart questions:

- What compostable or bio-based materials do you offer?

- Can your products handle specific load, clarity, or shelf-life needs?

- Are you customizing blends or just reselling imported stock?

Why this matters: Many suppliers rely on imported PLA granules—often mixed with plastic fillers that reduce compostability and sustainability integrity.

At Greenworksbio, we manufacture our entire product—from granules to end use—right here in India. Our unique starch-based PLA + PBAT blend is engineered for compostability, but also customizable for strength, clarity, sealability, and weight-bearing needs.

That means fewer compromises, stronger performance—and full control over compliance.

3. Factor in the Lifecycle, Not Just the Label

Some alternatives have a better end-of-life profile, but may require more energy or resources upfront. Others might last longer, but aren’t recyclable. The best choice depends on the application.

- For short-lived, single-use needs, like takeout packaging, compostables make sense.

- For longer-life or reusable contexts, like containers or display assets, materials like stainless steel or durable bamboo offer better returns.

A material’s “eco” value depends on both how it’s made and what happens after it’s used.

4. Work with Transparent, Innovation-Driven Suppliers

Greenwashing is common in this space. Look for suppliers that publish test data, clearly list certifications, and can explain material sourcing and disposal.

- Do they have region-specific compliance (like India’s CPCB approval)?

- Are they actively improving material performance or just rebranding conventional options?

Choosing a supplier that’s invested in continuous improvement helps you stay ahead of both regulation and customer expectations.

Why Certifications and Local Compliance Are Non-Negotiable?

As more states roll out restrictions on single-use plastics and global buyers adopt stricter procurement standards, using certified materials is no longer just an environmental choice—it’s a compliance one.

For high-volume categories like garbage bags, transparent carry bags, and shipping mailers, choosing products with recognized certifications (like ASTM D6400, EN 13432, or CPCB approval) helps teams stay audit-ready while meeting sustainability goals.

In India, this shift is already visible in sectors like:

- Retail chains are adopting transparent compostable bags that meet food safety and labeling standards

- Residential complexes moving to certified compostable garbage rolls as cities push wet/dry waste segregation

- E-commerce brands are switching to compostable courier bags that align with both sustainability policies and logistics workflows

That’s why more teams are moving beyond just “eco-friendly” claims and choosing certified plastic alternatives that are built for compliance, not just conscience.

Suppliers like Greenworksbio are stepping up to meet that demand—offering CPCB-approved, compostable products that don’t just check boxes, but perform under pressure across logistics, retail, and commercial use.

Why teams trust Greenworksbio as their plastic alternative partner:

- Certified to perform – ASTM D6400, EN 13432, ISO 17088, and CPCB-compliant

- Driven by R&D – In-house biotech and material science innovation

- Customer-first – Technical support and seamless product integration

- Safe by design – Non-toxic, food-safe, and built for compliance

→ Explore certified compostable products from Greenworksbio here.

Conclusion

Moving away from plastic isn’t about finding a one-size-fits-all replacement—it’s about making smarter choices, material by material, use case by use case.

Whether you’re sourcing packaging, streamlining logistics, or updating internal procurement policies, the alternatives are already here: compostable that perform, reusables that last, and natural materials that break down without a trace.

The best part? You don’t have to compromise on function to do better for the planet. With the right certifications, infrastructure awareness, and supplier alignment, sustainable materials can be a seamless part of modern operations, not a workaround.

The question isn’t whether plastic alternatives are ready. It’s whether your systems are ready to implement them—intentionally, and at scale.

Frequently Asked Questions

1. What are the best plastic alternatives for everyday products?

Some of the best plastic alternatives include biodegradable plastics, glass containers, reusable bags, cardboard boxes, and beeswax wraps. These materials are being used to replace traditional plastic items like bottles, food packaging, and utensils—offering a lower carbon footprint and safer disposal options.

2. Which plastic alternative products are safe for food storage?

For food containers and packaging, options like glass jars, stainless steel boxes, paper packaging, and beeswax-coated cloth wraps are popular. These sustainable alternatives are non-toxic, durable, and better suited for storing hot liquids and perishables compared to single-use plastic products.

3. Are there any eco-friendly alternatives to plastic wrap?

Yes—beeswax wraps, silicone lids, and glass food storage containers are some of the most effective eco-friendly alternatives to plastic wrap. They help reduce plastic waste, last longer, and require fewer natural resources like water and land during production.

4. What are the alternatives to plastic in packaging?

For businesses looking to shift from plastic packaging, materials like paper bags, cardboard, wood fiber, hemp, and wheat straw are gaining popularity. These sustainable plastic alternatives provide durability while reducing landfill pressure and pesticide exposure during production.

5. Why are sustainable alternatives to plastic gaining momentum in recent years?

In recent years, growing concerns around plastic pollution, human health, and land use have pushed industries toward sustainable alternatives like seaweed-based films, algae plastics, and coconut fibers. The move is also driven by policies like the Global Plastics Treaty and consumer demand for lower-impact materials.

6. Can biodegradable plastics replace plastic bottles and coffee cups?

Biodegradable plastics made from agricultural waste, corn starch, or jojoba oil are now being used for disposable coffee cups, bottles, and personal care containers. While they’re a great option in many contexts, proper disposal infrastructure is key to realizing their environmental benefits.