You’ve probably heard the terms, biodegradable, compostable, plant-based, recyclable. But when it comes to packaging, what actually qualifies as eco-friendly? And more importantly: what works without disrupting your operations, budget, or brand image?

In 2025, the pressure on businesses to reduce packaging waste is real—and rising fast. Regulatory frameworks are tightening, especially around plastic use. Consumers are paying closer attention to what shows up at their doorstep. And across industries—from skincare and food to pharma and logistics—teams are asking the same thing:

How do we find sustainable packaging materials that actually perform?

We are breaking down the most viable eco-friendly packaging materials available today—what they’re made of, how they behave in real supply chains, and where they make sense to use. Whether you’re looking for biodegradable material for packaging or exploring alternatives to petroleum-based plastics, you’ll find practical answers here.

What Are Eco-Friendly Packaging Materials?

Eco-friendly packaging refers to materials designed to minimize environmental impact across their lifecycle—from sourcing to disposal. These materials are often renewable, compostable, recyclable, or derived from waste streams, helping businesses shift toward a circular economy where nothing goes to landfill unnecessarily.

This includes materials that are:

- Renewable or bio-based (like sugarcane pulp, mushroom mycelium, seaweed)

- Recyclable or compostable under real-world infrastructure

- Low-impact in production (less energy-intensive, lower emissions)

- Safe at end-of-life, meaning they don’t release toxins or microplastics when breaking down

Common examples:

- Bioplastics like PLA or PBS (plant-based, compostable under industrial conditions)

- Molded fiber from recycled paper pulp or virgin kraft pulp

- Cellulose films (home-compostable, great for transparent packaging)

- Algae- or mycelium-based foams, which replace petroleum-based fillers

Each has different benefits—and limitations—depending on your product category, logistics system, and disposal context.

Why Sustainability in Packaging Is No Longer Optional?

Sustainable packaging isn’t just about swapping out plastic—it’s about rethinking the packaging system entirely.

For businesses, this shift is being driven by three urgent forces:

- Consumer pressure: Buyers are increasingly eco-conscious and often base purchasing decisions on a brand’s environmental credibility.

- Regulatory movement: Governments worldwide are imposing bans, taxes, and mandates on single-use plastics and excessive packaging.

- Operational resilience: Sustainable packaging materials often come with improved supply chain transparency, easier end-of-life management, and better alignment with ESG goals.

In short, packaging is now part of your brand’s footprint—and an early investment in eco-friendly packaging materials is both a reputational and compliance advantage.

6 High-Impact Plant-Based Packaging Materials to Know in 2025

As regulatory, operational, and consumer pressures converge, businesses are exploring next-gen packaging that isn’t just “eco-friendly” in name, but in sourcing, performance, and end-of-life behavior.

Here are six plant-based materials reshaping the future of sustainable packaging—and what makes each one functionally and commercially viable.

1. Bioplastics (PLA, PBS, PHA)

…

Best for: food containers, compostable mailers, retail packaging

Bioplastics are made from renewable crops like corn starch, sugarcane, or cassava and are engineered to mimic the structure and functionality of petroleum-based plastics.

Why it works:

- Supports drop-in replacement of PE and PP in rigid/flexible formats

- Certified variants (e.g., PLA under EN 13432) are industrially compostable

- Lower lifecycle emissions vs. fossil-based polymers

- Used in films, thermoformed trays, bottles, and cutlery

Watch-out: Not all bioplastics are compostable; some are only bio-based but behave like conventional plastic unless properly managed.

Looking for certified, performance-tested bioplastics?

Greenworksbio offers EN 13432 and ASTM D6400 compliant compostable materials engineered for real-world packaging use—delivering strength, sustainability, and peace of mind. Explore compostable packaging solutions →

2. Cellulose (Films, Paperboard, Molded Fiber)

Best for: dry food packaging, liners, transparent wraps

Derived from wood pulp, cotton, or hemp, cellulose-based materials are biodegradable, renewable, and function well across rigid and flexible formats.

Why it works:

- Available in home-compostable transparent films

- Strong barrier properties (moisture, grease) when coated or laminated

- Easily printed and converted in existing packaging lines

- Works well as a substrate coating for hybrid materials

- Used by: Ethical beauty brands, premium food labels, and compostable mailer startups.

3. Mushroom Mycelium (Structural Molding)

Best for: electronics, glassware, high-end fragile products

Mycelium is the root network of fungi, cultivated with agricultural waste (e.g. hemp husks), and grown into custom-shaped molds for protective packaging.

Why it works:

- Low water and energy input; grows in under a week

- Fully home-compostable and toxin-free

- Replaces EPS foam, PU, and plastic clamshells

- Ideal for shock absorption and insulation

Limitation: Custom tooling required for shape-based molds; currently used more in low-volume premium sectors. High-end production requires more investment in manufacturing.

4. Sugarcane Bagasse (Pulpy Molded Fiber)

Best for: foodservice containers, trays, disposable tableware

Bagasse is the fibrous byproduct left after sugarcane juice extraction. It’s widely used in molded packaging for F&B and QSR industries.

Why it works:

- High rigidity + heat tolerance (up to ~200°C)

- Biodegradable and compostable in both home and industrial settings

- Lightweight and printable

- Ideal for clamshells, plates, lids, trays, and takeaway packaging

- Used in: Airline meal trays, compostable coffee lids, and D2C food delivery formats.

5. Seaweed (Films, Edible Packaging, Biopolymer Blends)

Best for: single-use sachets, dry goods, edible wrappers

Seaweed-derived packaging uses red algae or brown seaweed extracts to form thin, flexible films. It’s gaining traction in the FMCG and personal care space.

Why it works:

- Requires no land, fertilizer, or freshwater to grow

- Absorbs CO₂ during cultivation (net-negative)

- Breaks down naturally in marine and soil environments

- Can be blended with other polymers for added structure

- Notable applications: Edible sauce sachets, water pods at marathons, and biofilm liners for hygiene products.

Limitation: Currently used more in low-volume premium sectors. High-end production requires more investment in manufacturing.

6. Coconut Husk (Coir Fiberboard and Fillers)

Best for: corrugated trays, structural inserts, molded boards

Coconut husk (coir) is a lignocellulosic material sandwiched between the shell and outer coat. It’s now being turned into rigid boards and bioplastic fillers.

Why it works:

- Naturally durable, lightweight, and compostable

- High lignin content makes it suitable for structural forms

- Often blended with wood dust or starch to create biodegradable packaging composites

- Used for trays, protective casing, and secondary packaging

- Used by: Eco-conscious electronics brands and niche D2C players prioritizing circularity.

What Makes a Packaging Material Truly Sustainable?

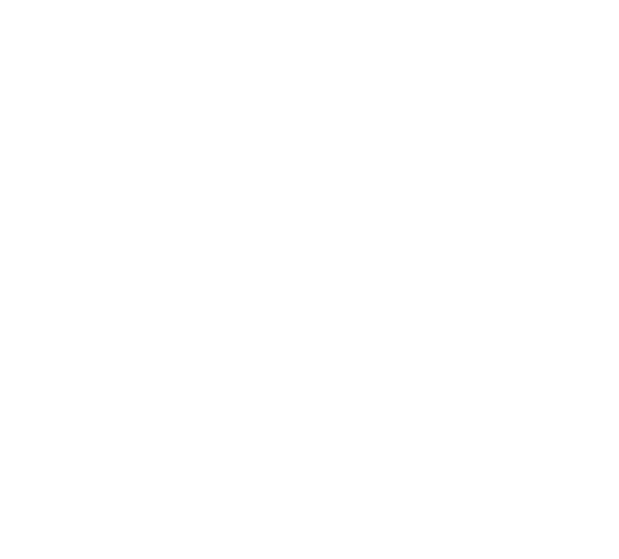

A material isn’t eco-friendly just because it’s “natural” or “biodegradable.” True sustainability is determined by:

1. Sourcing Impact

Is the material renewable or derived from recycled input? For example:

- FSC-certified paper ensures responsible forestry

- Bagasse (sugarcane residue) repurposes agricultural waste

- PLA bioplastics are plant-based but still industrially processed—requiring evaluation of land use and water footprint

2. Functional Lifecycle

Does the material last as long as the product needs it to—and then break down appropriately? Good materials offer protection, shelf life, and branding flexibility without creating downstream waste.

3. End-of-Life Options

Is the material recyclable, industrially compostable, or home-compostable? More importantly: does the infrastructure exist to support that pathway?

- Cellulose films work well in compost bins

- Bioplastics often fail if mistakenly sent to landfill or mixed into recycling streams

- Aluminum foil and PET may be recyclable in theory—but only if cleaned and sorted properly

4. Toxicity and Byproducts

Does the material leach toxins during degradation? For instance, oxo-degradable plastics fragment but don’t biodegrade—leading to microplastic pollution.

The goal is to choose packaging that works with your system, not against it.

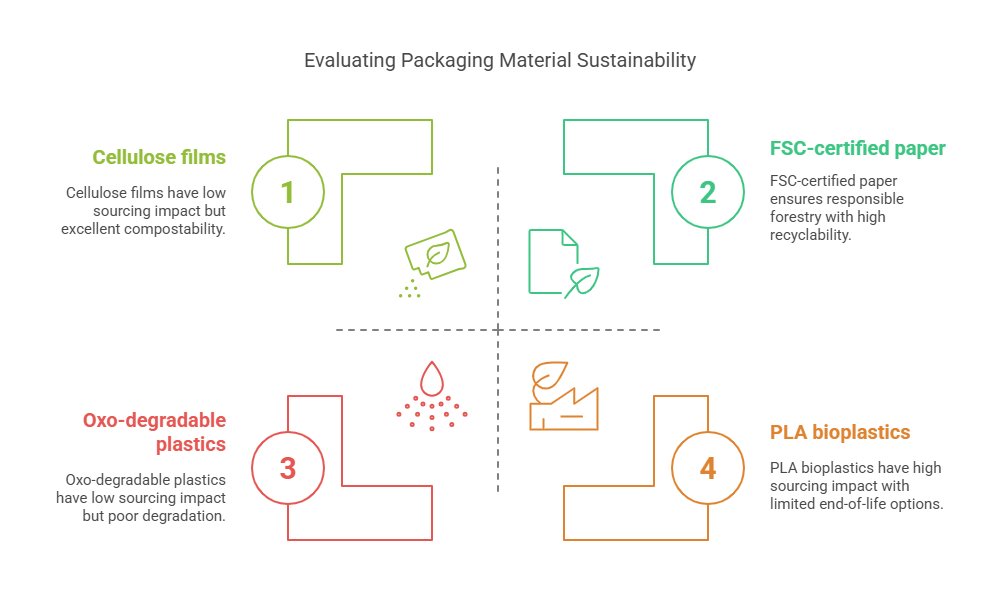

Operational and Brand Benefits of Sustainable Packaging

Eco-friendly packaging isn’t just a trend—it’s becoming a strategic lever for risk mitigation, regulatory readiness, and supply chain efficiency. While the environmental upside is well understood, the operational and commercial benefits are equally compelling.

Here’s a breakdown of where the value lies—backed by both environmental science and procurement logic.

1. Tangible Reductions in Environmental Impact

Traditional plastic packaging accounts for over 40% of all plastic waste (Source), most of which is neither collected nor recycled effectively. By contrast, certified eco-materials like CPCB-approved compostables, FSC-certified papers, or bio-based polymers (like PLA, PHA) significantly reduce this downstream footprint.

Key impact levers:

- Lower embodied carbon: Biobased packaging often emits 30–70% less CO₂ across production.

- Degradability with infrastructure: Industrially compostable films (e.g., EN 13432 compliant) break down within 90–180 days—versus 400+ years for poly-based films.

- Reduced fossil dependency: Renewable feedstocks (e.g., bagasse, wheat straw) decouple packaging from volatile petroleum markets.

Some materials even go further—like carbon-negative hemp fiberboard or seaweed-based films that sequester CO₂ during growth.

2. Alignment With Evolving Consumer Expectations and Brand Value

Today’s buyers—especially Gen Z and millennial segments—don’t just prefer green packaging. They expect it. A McKinsey report shows over 60% of consumers globally consider sustainability in purchasing decisions, and packaging is the most visible touchpoint.

Eco-packaging signals:

- Trust: Transparency in sourcing and materials

- Accountability: Participation in circular economy models

- Leadership: Willingness to adapt before mandates require it

Brands using sustainable packaging often report:

- Improved NPS (Net Promoter Score)

- Higher retention rates among eco-conscious consumers

- Expanded shelf appeal in retail and D2C channels

3. Long-Term Cost Efficiencies and Operational Gains

Yes, some eco-materials have a higher unit cost. But the total cost of ownership (TCO) often tilts in favor of sustainability over time:

- Waste management savings: Compostable packaging reduces landfill tipping fees and simplifies segregation.

- Lightweighting and compact design: Paper-pulp or molded fiber trays often reduce dimensional weight charges in shipping.

- Recycled input = cheaper sourcing: Some materials (e.g., recycled cardboard) are eligible for circular supply chain credits or tax incentives.

- Lower ESG risk exposure: Companies using certified sustainable packaging are less vulnerable to regulatory fines or procurement disqualification.

Add in the growing access to material innovation hubs and local manufacturing partners, and eco-packaging is increasingly both cost-competitive and supply-chain resilient.

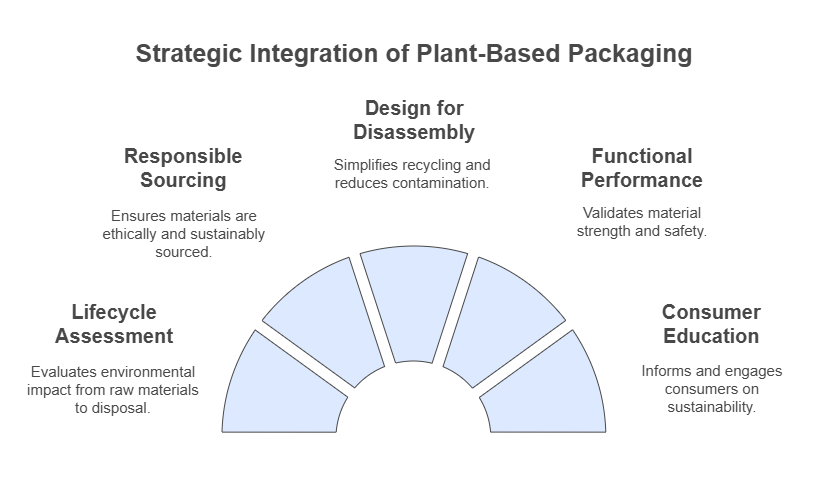

5 Strategic Approaches to Integrating Plant-Based Packaging

Switching to plant-based packaging isn’t just a materials decision—it’s a system-level change that touches design, logistics, compliance, and customer experience. The following five strategies can help you scale responsibly, without compromising function or performance.

1. Conduct a Lifecycle Assessment (LCA)

Understand true environmental cost before you scale

A Life Cycle Assessment evaluates the total impact of a packaging solution—from raw material extraction through manufacturing, distribution, use, and end-of-life.

For plant-based materials, consider:

- Agricultural inputs: land use, water consumption, pesticide impact

- Processing energy: fermentation for bioplastics, pulping for cellulose

- Disposal efficiency: compostability vs. landfill leakage vs. recyclability

Running an LCA ensures you aren’t simply swapping one problem (plastic) for another (resource-intensive biomass).

2. Prioritize Certified, Responsible Material Sourcing

Your packaging is only as credible as its supply chain

Partnering with vetted suppliers—and demanding certifications—brings traceability to your materials. Look for:

- FSC / PEFC for paper and fiber sourcing

- BPI / TÜV Austria for compostability standards

- Rainforest Alliance or Fairtrade for ethical agricultural inputs

Certification aligns your operations with global EPR and green procurement frameworks—critical for export markets and public sector bids.

3. Design for Disassembly and Separation

Make it easy to break down—and even easier to recycle

Avoid multi-layer laminates or materials fused with incompatible plastics. Instead:

- Use mono-material or snap-fit designs

- Incorporate clear disposal labeling (e.g., How2Recycle, OK compost logos)

- Enable consumer-facing dismantling—e.g., compostable sleeve + recyclable jar

This reduces contamination and improves recovery rates across composting and recycling systems.

4. Validate Functional Performance Through Rigorous Testing

Green doesn’t mean weak—especially in transit, moisture, or shelf life

Your material choice must perform under pressure, literally. Test for:

- Compression strength (corrugates and molded fiber)

- Oxygen and moisture barrier (cellulose films, bio-coatings)

- Shelf life and safety for perishables

- Product leakage, staining, or deformation under temperature or humidity extremes

5. Educate and Engage Through Packaging Itself

Build behavior change and brand trust at the same time

Most consumers can’t tell PLA from PET, or home compostable from recyclable. Help them:

- Use QR codes linking to disposal instructions

- Include impact claims (e.g., “This tray saves 50g of plastic per use”)

- Share LCA insights or supplier certifications via inserts or your website

Packaging becomes a sustainability story in itself—building brand loyalty and supporting transparency.

Eco-Friendly Packaging in Action: Sector-by-Sector Examples

There’s no one-size-fits-all when it comes to sustainable packaging. Each industry has distinct functional demands, compliance needs, and consumer expectations. Here’s how plant-based and biodegradable packaging is being smartly applied across sectors:

1. Food & Beverage: Freshness Meets Compostability

Best-fit materials: PLA films, cellulose coatings, bagasse trays, starch bioplastics

- Need: Moisture resistance, food safety, shelf life

- Solutions:

- Bagasse for compostable clamshells, meal trays

- PLA/starch-based films for wrap, cutlery, and flexible pouches

- Cellulose films with oxygen barriers for dry foods

Bonus: These formats often meet food contact regulations (FDA, EU 10/2011) and are accepted in industrial composting streams.

2. Health & Beauty: Shelf Appeal With Substance

Best-fit materials: Biopolymer tubes, refillable bioplastics, molded pulp jars

- Need: Premium branding, durability, chemical resistance

- Solutions:

- Refillable containers made from bio-PET or recyclable HDPE

- Compostable sachets for dry formulas (e.g., shampoo powders)

- Mycelium or bagasse-based gift boxes and molded inserts

Trend: Beauty brands are shifting toward refill-first packaging ecosystems, using plant-based formats for outer packaging and shipping.

3. Technology & Electronics: Rethinking Protection Without Foam

Best-fit materials: Mycelium molds, molded pulp, coco coir inserts

- Need: Impact resistance, anti-static properties, custom fit

- Solutions:

- Mushroom packaging for laptops, headphones, and glassware

- Paper-based thermal protection (instead of plasticized foams)

- Coconut fiber + starch composites for cable organizers, router packaging

Win: These reduce reliance on EPS and EPE foams, both of which are difficult to recycle and often banned in export markets.

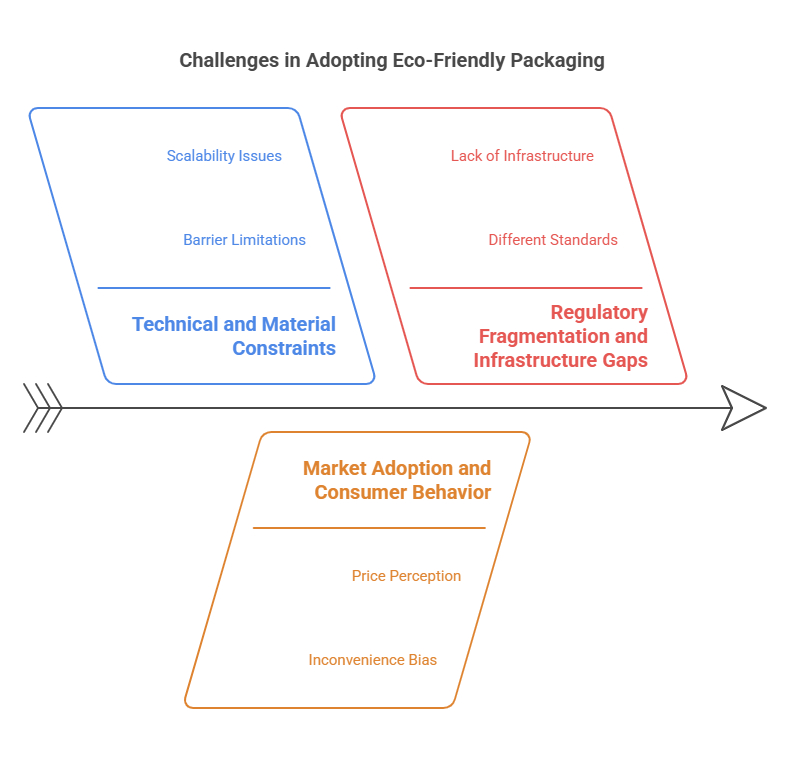

3 Challenges Slowing the Shift to Eco-Friendly Packaging

Eco-friendly packaging holds immense promise—but the path to large-scale adoption is not frictionless. From material engineering gaps to infrastructure mismatches and regulatory inconsistencies, businesses must navigate a range of hurdles before sustainable packaging can fully displace its conventional counterparts.

Here’s a breakdown of the biggest roadblocks—and why understanding them is critical to solving them.

1. Technical and Material Constraints

Green materials must evolve without compromising protection, shelf life, or supply chain resilience

While plant-based and biodegradable materials offer strong sustainability benefits, they still lag behind traditional packaging in certain performance areas:

- Barrier limitations: Materials like PLA or paper-based packaging often struggle with oxygen, moisture, or grease resistance—critical for F&B and pharma.

- Shelf life & perishables: Compostable films can degrade too quickly in high-humidity or refrigerated conditions.

- Strength and impact tolerance: Alternatives to foams (like mycelium or molded fiber) need optimization for heavy, fragile goods.

On top of functionality, scalability remains a challenge. Many promising materials (e.g., seaweed, hemp fiberboard) are still cost-intensive at scale or lack mature production pipelines.

Mitigation strategy: Brands are increasingly investing in hybrid packaging—e.g., combining biopolymers with barrier coatings—or using LCA tools to balance function with impact trade-offs.

2. Market Adoption & Consumer Behavior

Eco-conscious preferences exist—but they don’t always convert to consistent action

Even though 60–70% of global consumers say they care about sustainability (Source), that doesn’t always translate to purchase behavior. Why?

- Price perception: Plant-based materials often cost more, and that premium can’t always be passed to the end-user.

- Inconvenience bias: Recyclability or compostability may require sorting, cleaning, or drop-off that consumers aren’t equipped or motivated to follow.

- Label confusion: Terms like “biodegradable,” “oxo-degradable,” and “home-compostable” are frequently misunderstood—leading to greenwashing fatigue.

Mitigation strategy: Clear on-pack labeling, consumer education, and visible certifications (e.g., BPI, TÜV, FSC) can build trust and trigger behavior change.

3. Regulatory Fragmentation & Infrastructure Gaps

Sustainability doesn’t scale well when rules and infrastructure vary by region

For global or multi-market businesses, navigating eco-friendly packaging laws is anything but straightforward:

- Different standards: A material certified as compostable under EN 13432 may not meet ASTM D6400 standards in the U.S.—creating issues for multinational compliance.

- Inconsistent enforcement: While countries like France or India have imposed aggressive plastic bans, others still lack enforcement or offer loopholes for single-use materials.

- Lack of downstream infrastructure: Compostables that enter landfills (due to lack of collection) behave like traditional plastics—neutralizing any claimed environmental benefit.

Mitigation strategy: Brands are leaning into region-specific packaging strategies, and aligning procurement with areas where composting, take-back, or EPR infrastructure is already mature.

Conclusion

Plant-based and biodegradable materials are unlocking new levels of performance, circularity, and brand value—but they also come with trade-offs. Navigating these successfully requires more than good intentions. It demands data-backed material selection, functional testing, region-aware compliance, and continuous consumer education.

The businesses that lead this shift aren’t the ones with the flashiest claims—but those that embed sustainability into the full packaging lifecycle, from design to disposal.

Because at the end of the day, better packaging isn’t just about protecting what’s inside—it’s about protecting what’s next.

Frequently Asked Questions

What is the best eco-friendly packaging material for reducing carbon footprint?

The best solution depends on your use case, but molded pulp, PLA-based bioplastics, and FSC-certified paper packaging are top choices for businesses aiming to cut their carbon footprint. These eco friendly packaging materials use fewer fossil inputs and release less CO₂ during production and disposal. For measurable impact, many companies in the United States now run a Life Cycle Assessment (LCA) before selecting the right packaging.

How does eco-friendly packaging apply to the food industry?

In the food industry, packaging must protect freshness and meet food-safety regulations. Biodegradable packaging material like bagasse, starch-based films, and cellulose wraps are increasingly used as zero-waste alternatives to plastic trays, containers, and wrappers. These options are especially effective in QSR, meal kits, and fresh produce applications.

Is recyclable packaging always the most sustainable option?

Not necessarily. Recyclable packaging is a strong step toward circularity, but its real impact depends on access to proper recycling infrastructure. In many parts of the United States, only certain materials—like PET or uncoated paper—are widely accepted. Sometimes, a compostable eco friendly packaging material is the better choice, particularly when organic waste streams exist.

What materials are considered eco friendly for pharmaceutical packaging?

Eco friendly pharmaceutical packaging material must meet strict safety, barrier, and compliance standards. Materials like recyclable aluminum, glass, or cellulose-based blister alternatives are emerging as sustainable options. While this sector is traditionally hard to decarbonize, newer eco friendly material for packaging—such as mono-material bio-based films—are gaining ground and helping reduce medical plastic waste.

How can I choose the right eco-friendly material for packaging my product?

Start by identifying the functional needs—barrier performance, shelf life, branding—and match them with various materials like paperboard, PLA, or molded fiber. Then, test for regulatory compliance and customer convenience. Choosing the right packaging also means factoring in logistics and end-of-life handling: recyclable, compostable, or reusable.

Can paper packaging really help achieve zero waste goals?

Yes—paper packaging made from recycled or FSC-certified sources plays a key role in zero-waste strategies, especially when it’s uncoated and home-compostable. It’s already being adopted across industries ranging from retail to friendly packaging solutions in cosmetics and FMCG.