Many believe the problem with plastic bags starts with disposal. In reality, it begins much earlier—with fossil fuel extraction, energy-intensive processing, and the use of finite resources to create something used for minutes but lasting centuries.

And despite what some labels suggest, plastic bags are rarely recycled. They clog sorting machines, are rejected due to food or product contamination, or end up polluting waterways and ecosystems as microplastics.

So the real question isn’t just how to use fewer plastic bags, but:

What practical, scalable alternatives exist—and which ones make sense for both consumers and businesses?

This blog explores six proven alternatives to plastic bags, including certified compostable materials and durable reusable options—focusing on what works in everyday life and under real supply chain conditions.

Why It’s Time to Rethink Shopping Bags?

Plastic bags persist in many industries—not because they’re ideal, but because they’re convenient. They’re cheap, lightweight, and widely available. But their environmental footprint far outweighs their short-term utility.

From extraction to disposal, the life cycle of a plastic bag is resource-heavy and polluting. Most are made from petroleum-based materials, used once, and then either landfilled, incinerated, or leak into ecosystems. They break down into microplastics and disrupt marine and soil health for decades.

According to UNEP, over 50% of plastic packaging waste comes from single-use items like shopping bags (Source), making them a primary target for legislation and sustainability mandates.

For businesses, phasing out plastic bags is no longer a CSR afterthought—it’s a strategic move. Here’s why more procurement teams and brand owners are moving toward certified alternatives:

- Reduced backend waste: Compostable or reusable bags reduce landfill volume and boost EPR compliance.

- Platform and retail requirements: Many marketplaces and logistics partners now require plastic-free shipping materials.

- Brand value and visibility: Customers associate compostables or natural fibers with transparency, care, and innovation.

- Longer lifecycle ROI: While upfront costs may be higher, reusable or biodegradable bags offer better cost-per-use over time.

- ESG leadership: Brands using scalable alternatives gain ground in sustainability reporting, investor perception, and regulatory readiness.

In short, the infrastructure now exists to support a large-scale shift away from plastic bags. What’s needed is clarity on the right materials—and how to integrate them without disrupting operations.

Top 6 Eco-Friendly Alternatives to Plastic Bags

If you’re looking to reduce your plastic use—personally or as a brand—these seven bag alternatives offer a practical way forward. Each one has unique strengths and ideal use cases depending on your needs.

1. Certified Compostable Bioplastic Bags (PLA+PBAT)

Best for: Brands, retailers, and delivery operations that need a plastic-like experience with a lower environmental cost.

Made from starch-based, plant-derived polymers, these bags are designed to decompose within 90–180 days in industrial composting facilities. They carry certifications such as CPCB (India), EN 13432, and TÜV Austria, making them viable for both domestic and export compliance.

- Pros: Mimics plastic in strength and appearance; certified compostable; low carbon footprint

- Cons: Shorter shelf life; needs access to composting infrastructure

→ Explore certified compostable bag solutions designed for Indian and global waste systems.

2. Fresh Produce & Grocery Liners

Best for: Supermarkets, hyperlocal grocers, and zero-waste stores

Lightweight compostable liners help replace single-use HDPE produce bags. These bags are breathable and reduce condensation, keeping fruits and vegetables fresher for longer.

Pros

- Food-safe and breathable

- Compostable in municipal or industrial systems

- Reduces in-store plastic footprint

Cons

- Not ideal for heavy or wet goods

3. Food Delivery & Takeout Bags

Best for: Cloud kitchens, QSR chains, and restaurants

These starch-based bags are grease-resistant and heat-tolerant, ideal for food deliveries. Reinforced for weight and customizable in size, they offer a compliant, plastic-free alternative for F&B packaging.

Pros

- Withstands hot and oily contents

- Printable for food safety labels or branding

- Supports FSSAI and CPCB regulations

Cons

- Must be composted within a specified time window

4. Garbage Bin Liners (Domestic & Commercial Use)

Best for: Households, apartment complexes, offices, and waste collection agencies

Compostable bin liners are critical for cities enforcing wet/dry waste segregation. These starch-based bags break down safely with organic waste and reduce landfill pressure.

Pros

- Fits standard bin sizes

- Decomposes without releasing toxins

- Aligned with municipal solid waste rules

Cons

- Not suitable for sharp or abrasive waste

5. Reusable Format Bags (Multi-Use PLA+PBAT Hybrids)

Best for: Events, retail promotions, or reuse-focused programs

These bags are made with slightly thicker blends designed for 5–10 reuse cycles. Ideal for brands looking to offer “low-impact reusable” options with a compostable end-of-life pathway.

Pros

- High load-bearing capacity

- Good for gifting or branded campaigns

- Compostable after multiple uses

Cons

- Higher unit cost; may not replace long-term fabric bags

6. Flexible Wraps & Secondary Packaging Films

Best for: Apparel packaging, FMCG sachets, inner wraps, or bakery use

Transparent or matte starch-based films offer moisture control, barrier properties, and branding potential—without petroleum-based polymers. These are used as inner liners, wraps, or even primary packaging in low-moisture products.

Pros

- Customizable thickness and finish

- Printable and sealable

- Breaks down fully in compostable conditions

Cons

- Limited shelf life in humid environments

Knowing what works is one thing—sourcing it is another. Greenworksbio simplifies the switch with CPCB-certified, ready-to-use bag solutions.

See what’s available →

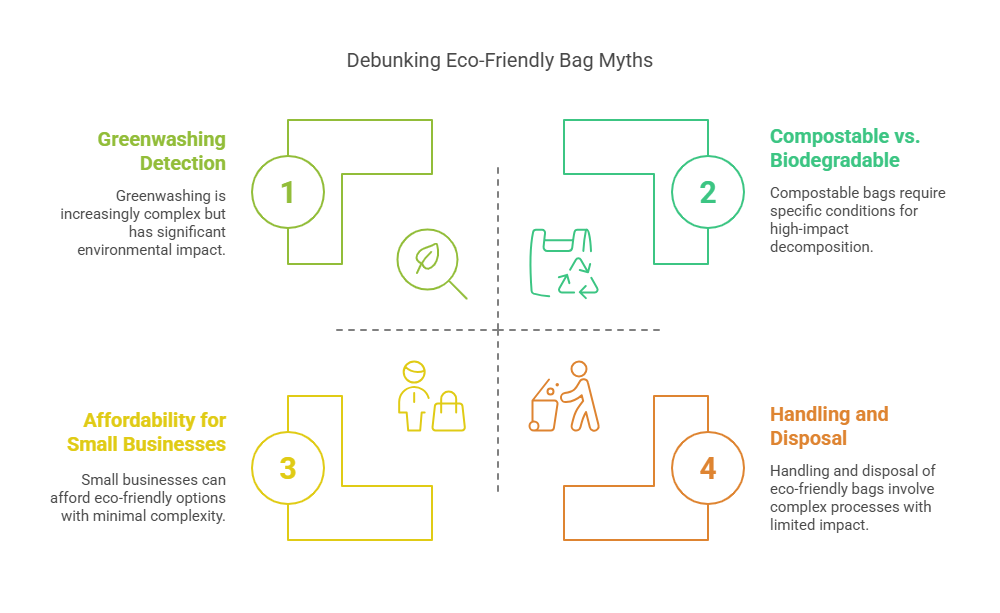

Debunking the Most Persistent Myths About Eco-Friendly Bags

Even as awareness grows, some outdated beliefs continue to hold people back from making the switch. Let’s clear up a few that often get overlooked—but matter just as much.

Myth 1: “Compostable and biodegradable mean the same thing.”

Not quite.

Biodegradable simply means a material can break down over time, eventually. Compostable means it breaks down within a specific timeframe, under defined conditions, and without leaving toxic residue.

Compostable bags (like those certified to ASTM D6400 or EN 13432 standards) decompose fully in industrial composting environments—usually within 90 to 180 days.

Myth 2: “Greenwashing is easy to spot.”

In reality, it’s getting harder.

Many products labeled “eco” or “biodegradable” don’t meet certification standards. Some may degrade into microplastics. Others use misleading language or vague claims without third-party proof.

Always look for clear certifications, like CPCB-approved compostable logos in India or EN 13432 in the EU.

Myth 3: “Only big brands can afford to switch.”

Not anymore.

Compostable and reusable bag prices have dropped significantly in recent years. With low MOQs and custom branding available, small businesses can now access the same sustainable options without breaking budgets.

Bonus: Customers are often willing to pay a little more for brands that align with their values.

Myth 4: “Eco-friendly bags always outperform plastic.”

Not always—and that’s okay.

Some alternatives require different handling, care, or disposal. For example, compostable bioplastics need the right bin; cotton bags need regular washing. The goal isn’t perfection—it’s progress with purpose.

Choose based on context, not just headlines. One material won’t suit every use case, but there’s always a better fit than plastic.

How to Choose the Right Alternative to Plastic Bags?

Step 1: Identify the Primary Use Case

The right material depends on how the bag will be used:

- Grocery or delivery bag (single-use): Certified starch-based compostable (PLA+PBAT) bags that also ensure durability.

- Moisture exposure (produce, frozen items): Compostables with water resistance or coated kraft paper

- Retail checkout or gifting: Matte-finish compostable bags or untreated jute

- Light transport (in-store carry): Kraft paper or compostable liners

Many single-use plastic bags can be directly replaced by compostable solutions already available in multiple formats.

Step 2: Think About Frequency of Use

Even when replacing single-use plastic, usage frequency matters:

- Low reuse (1–3 uses): Choose industrially compostable PLA+PBAT bags

- Moderate reuse (5–10 uses): Go for thicker compostable bags or kraft paper with reinforced handles

- High reuse scenarios: Reusables like untreated cotton or jute bags are ideal (but not meant for replacing single-use formats)

Avoid defaulting to NWPP or synthetics for limited-use cases—they can become just another type of waste.

Step 3: Match the Disposal Pathway

Even the best bag is only as sustainable as the infrastructure it’s paired with.

| Material | Disposal Option | Requirements |

|---|---|---|

| Starch-based PLA+PBAT | Industrial composting | Requires compost collection, CPCB-compliant setup |

| Uncoated kraft paper | Compostable / Recyclable | Avoid plastic coating for full breakdown |

| Jute / untreated cotton | Backyard compostable | Best with dry organic waste, no plastic blends |

| NWPP / Polyester | Recyclable (conditionally) | Requires textile or polymer-specific recovery |

Tip: Always align your material with what disposal options your target audience realistically has access to.

Step 4: Consider Lifecycle Impact

When replacing single-use plastic, it’s not enough to look at end-of-life. Ask: what’s the full environmental cost of producing this bag?

- Starch-based compostables: Ideal for replacing single-use items with minimal carbon footprint

- Paper bags: Biodegradable but higher in raw material and water use

- Cotton/jute bags: High input costs—should only be used when true reuse is expected

- Synthetics: Effective only when reused long-term and properly recovered

If you’re choosing for B2B or enterprise use, use LCA tools like the Higg Index or Ecoinvent to assess total impact.

Step 5: Check for Recognized Certifications

Don’t rely on claims like “eco” or “biodegradable”—look for verifiable, regulated certifications, especially when replacing single-use plastics.

Key standards include:

- Compostability: EN 13432, ASTM D6400, ISO 17088

- India-specific compliance: CPCB, CPET

- Material sourcing: GOTS (organic cotton), FSC (paper), TÜV Austria (compostables)

Step 6: Factor in Messaging & Brand Perception

Offering compostable bags or low-impact packaging isn’t just a sustainability choice—it’s a brand statement. Clear materials, disposal guidance, and certifications signal accountability and help customers make better decisions.

Best practices:

- Print disposal instructions or composting symbols on the bag

- Use QR codes to link to environmental info or impact reports

- Educate teams and partners about correct usage

Looking to align with EPR mandates or reduce landfill costs? Greenworksbio offers compostable bags designed for regulatory and operational performance.

Explore certified options →

Conclusion

Every plastic bag replaced is a small win—but multiplied across choices, customers, or cities, it adds up fast.

Whether you’re sourcing bags for your business or rethinking your own daily habits, the right alternative isn’t just better for the environment—it’s a signal of the kind of future you want to help build.

Choose smart. Choose reusable. Choose better than single use plastic.

Because what you carry says something about what you stand for.

Frequently Asked Questions

What are the most sustainable materials for reusable bags?

Cotton, jute, and bamboo are among the most sustainable materials for reusable bags due to their natural origins, low environmental footprint, and biodegradability. Additionally, recycled materials like non-woven polypropylene and Green PE also present feasible options with considerable sustainability benefits.

Are compostable bioplastic bags really eco-friendly?

Yes, compostable bioplastic bags are more eco-friendly than traditional plastic bags. They are derived from plant extracts which are less harmful to the environment and can decompose within months, making them a preferred choice for those seeking to reduce plastic pollution.

What are 3 alternatives to plastic?

Three noteworthy alternatives to plastic are compostable bioplastic bags, made from plant extracts; cotton bags, derived from renewable crops, including hemp; and jute bags, made of spun vegetable fibers, all made from recyclable materials. All these alternatives are sustainable, durable and play a crucial role in reducing the amount of plastic waste.

How to make eco-friendly plastic bags?

Eco-friendly plastic bags, like Green PE, are often made by deriving ethanol from plants, such as sugarcane, which is then converted into polyethylene. However, creating such bags involves complex industrial processes that might not be feasible for individual, at-home production.

What are the solutions to plastic bags?

The solutions to plastic bags involve eliminating their use wherever possible and substituting them with reusable and sustainable alternatives. This includes compostable bioplastic bags, cotton bags, jute bags, recycled paper bags, bamboo bags, non-woven polypropylene bags, and even the average plastic bag, alongside reusable synthetic fabric bags.