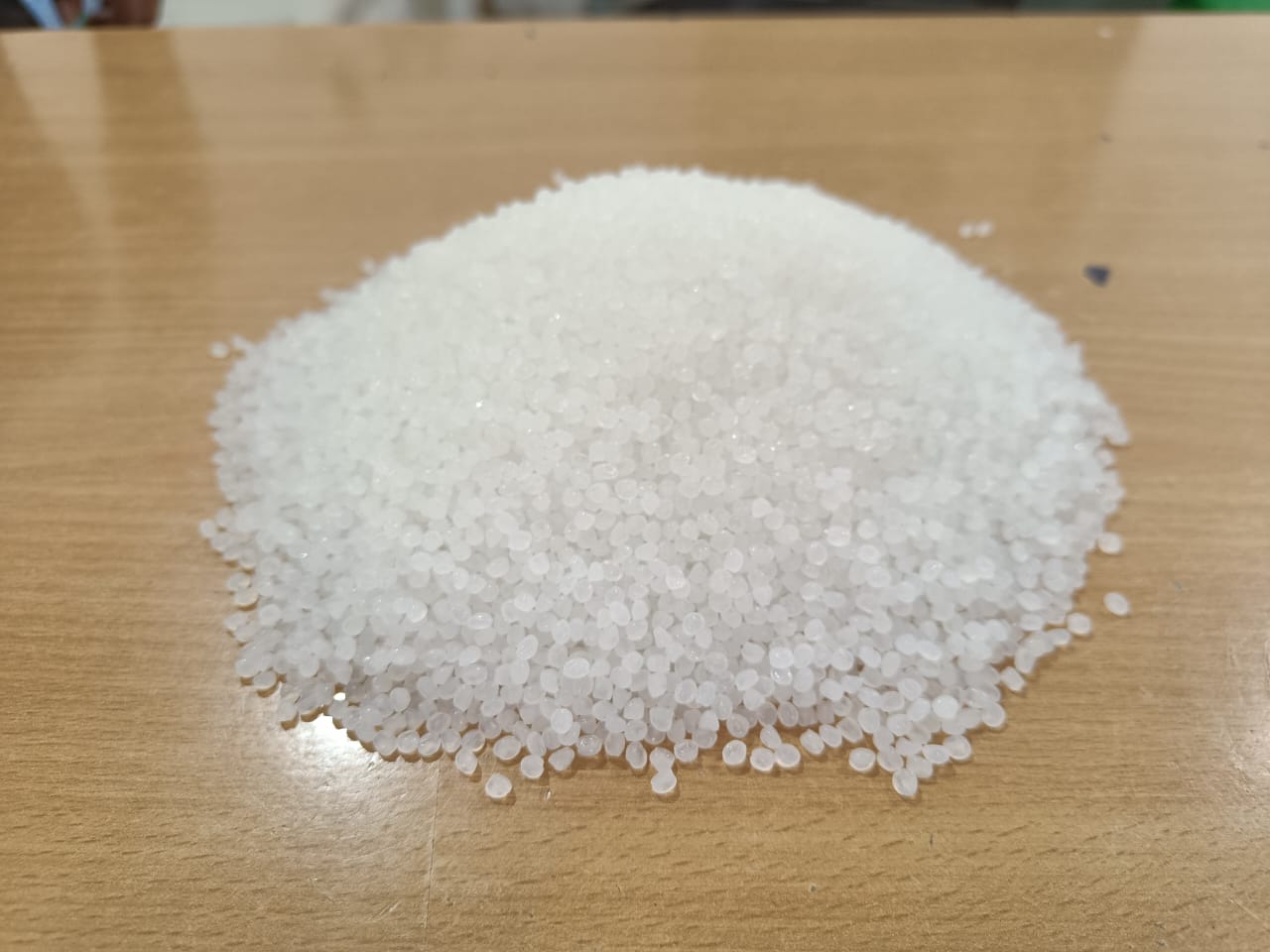

Injection Molding Resin

Certified Injection Molding Resin Suppliers for Bioplastics

Greenworksbio’s IMGWB001 is a compostable resin specifically engineered for polymer injection molding applications. Formulated with a PLA+PBAT blend, it is ideal for creating durable, food-safe products like cutlery, trays, lids, and molded components. Fully customizable, this bio-resin balances mechanical strength with environmental performance, helping businesses transition away from conventional plastic.

What Makes Greenworksbio Resin Supplier Right For Manufacturers & Brands?

- Precision Molding & Dimensional Stability

Engineered for smooth flow and high-detail accuracy in injection molding applications. - Compostable & Food-Safe Formulation

Made from PLA+PBAT, compliant with ISO 17088 and validated by CIPET for safe, sustainable use. - Wide Application Compatibility

Ideal for manufacturing cutlery, trays, sporks, lids, and caps across foodservice and healthcare sectors. - End-to-End Indian Manufacturing

Complete control from granule production to final molded goods—no imports, no fillers. - Custom Resin Engineering

Strength, cycle time, finish, and mold-fit can be tailored to suit specific operational needs.

Common Applications & Use Cases Across Industries

Industry | Common Applications |

|---|---|

| Foodservice/QSRs | Compostable forks, spoons, knives, sporks |

| Hospitality & Airlines | Tray sets, stirrers, takeaway packaging lids |

| Healthcare & Retail | Molded bioplastic components, caps, closures |

Technical Specifications

Parameter |

Specification |

|---|---|

| Material Composition | PLA + PBAT (biodegradable, food-contact safe) |

| Grade | IMGWB001 – Injection molding bio-polymer |

| Custom Formulations | Customizable for strength, mold cycle, clarity, or rigidity |

| Shelf Life | 12 months (under cool, dry storage) |

| Processing Temperature | 160–190°C (varies by mold type and thickness) |

| Mold Compatibility | Works with standard polymer injection molding machines |

Certifications & Compliance

ISO 17088

Compostability standard

CIPET Validated

Material strength and biodegradability validated

CPCB Certified

Certified by India’s Central Pollution Control Board

EN 13432 (TÜV Austria – In Progress)

In progress for OK Compost Industrial

FAQs

What should I consider when choosing resin for injection molding?

When selecting resin for injection molding, it’s essential to evaluate mechanical properties like tensile strength, impact resistance, chemical resistance, and heat resistance. The right injection polymer must align with your product’s functional demands—whether you’re producing food containers, medical plastic injection molding components, or plastic parts for the automotive industry. Additional considerations and key differences include water absorption, wall thickness, and the resin’s compatibility with your plastic injection molding setup.

How does polymer injection molding affect impact resistance and dimensional stability?

Polymer injection molding is the right material that enhances the ability to create precision-molded plastic parts with excellent impact resistance and dimensional stability—critical for high-performance components like lock systems, power tool bodies, and conveyor belts. Bio-based resin injection molding materials, such as PLA+PBAT blends, also offer good fatigue resistance for plastic products and are well-suited for higher impact strength structural applications across consumer products and medical devices.

What’s the typical melting point range for bio-based plastic resins?

Bio-based resins used in plastic injection molding materials—particularly injection polymers like PLA+PBAT—typically have material properties of a melting point of 160°C to 190°C. These materials balance a high melting point with low water absorption and thermal expansion, which are critical in both low and higher temperature environments.

Are injection molding resin suppliers offering food-grade certified options?

Yes, leading injection molding resin suppliers, including Greenworksbio’s, provide food-safe, certified compostable materials designed for resin injection molding. These plastic injection molders are ideal for applications such as cutlery, tray systems, caps, and plastic bags, especially within consumer packaging, QSRs, and healthcare industries. Certifications like ISO 17088, along with ongoing testing for gamma radiation tolerance and chemical resistance, ensure desirable properties and safe usage in plastic injection molding of food-contact items.

Why is resin selection critical for injection molding projects?

Resin selection is an important consideration that directly influences product strength, safety, and production efficiency in any injection molding project. Factors like ultimate tensile strength, thermal expansion, low dimensional stability, and resistance to extreme temperatures must be weighed carefully. For products requiring good fatigue resistance, and variety of applications, chemical resistance, or precision (like pulley wheels or electrical components), the right resin for injection molding is what ensures product integrity across a wide variety of industries.